Oil seals for cars

Table 1: The functions of the various components

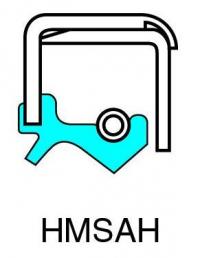

Replacing a crankshaft front oil seal

To ensure the longevity and effectiveness of the wheel hub oil seal, it is essential to perform regular maintenance checks. This includes inspecting the seal for any signs of wear, damage, or leaks This includes inspecting the seal for any signs of wear, damage, or leaks This includes inspecting the seal for any signs of wear, damage, or leaks This includes inspecting the seal for any signs of wear, damage, or leaks

This includes inspecting the seal for any signs of wear, damage, or leaks This includes inspecting the seal for any signs of wear, damage, or leaks wheel hub oil seal. If any issues are detected, it is recommended to replace the seal promptly to prevent further damage.

wheel hub oil seal. If any issues are detected, it is recommended to replace the seal promptly to prevent further damage.

spark plug axia. There are several different types of shaft oil seals, including lip seals, mechanical seals, and labyrinth seals. Lip seals are the most common type and consist of a flexible lip that comes into contact with the shaft. Mechanical seals, on the other hand, use mechanical components to create a seal, while labyrinth seals have multiple barriers to prevent the entry of contaminants. The world of automotive technology is constantly evolving, and with that comes the need for new and improved parts to keep engines running smoothly. One such part is the spark plug, a critical component that generates the spark necessary to ignite the fuel-air mixture in an internal combustion engine. Iridium Spark Plug, a revolutionary new product, is set to redefine the spark plug industry with its advanced technology and performance. When it comes to automotive issues, one of the most critical and potentially damaging problems is a car overheating. This phenomenon can stem from various factors, but when unchecked, it can lead to severe engine damage, particularly involving the head gasket. One of the key features of the axia spark plug is its iridium tip. Iridium is a rare and valuable metal that is known for its high melting point and resistance to corrosion. The use of iridium in the spark plug tip ensures a consistent and powerful spark for ignition. This results in improved fuel efficiency and reduced emissions from the engine

spark plug axia. Regular maintenance of the spark plug is essential to ensure optimal performance. This includes checking the spark plug for wear and tear, cleaning it as needed, and replacing it when necessary. By taking proper care of the spark plug, you can help prolong the life of your engine and ensure smooth operation.

Acrylic rubber (ACM)

By first finding out the dimensions of the inner and outer diameters and the height of the bore, you have all the data for the correct size of the oil seal. Of course, the oil seal must also be able to withstand the pressure, temperature and medium it is exposed to within the seal during the manufacturing process. You can read more about this in our oil seal selection guide.