Links:

Once you've selected the right paint, applying a sealant is the next step in achieving a professional-grade finish

.2. Weather Resistance Self-adhesive foam seals are designed to withstand harsh environmental conditions. They offer excellent resistance against moisture, UV rays, and extreme temperatures, ensuring that seals maintain their integrity over time. This characteristic makes them ideal for outdoor applications, such as sealing windows and doors in residential and commercial buildings.

One of the key benefits of rotating mechanical seals is their ability to accommodate shaft movement and misalignment while still maintaining a secure seal. This flexibility is especially important in applications where the shaft is subject to vibration, thermal expansion, or other factors that could cause it to move or shift during operation. By allowing for some degree of movement, rotating mechanical seals can effectively prevent leakage even in challenging operating conditions.

1. Energy Efficiency One of the primary benefits of installing adhesive weather stripping is its potential to significantly improve energy efficiency. By sealing gaps, the need for heating in the winter and cooling in the summer is reduced, leading to lower energy bills. According to the U.S. Department of Energy, sealing air leaks can save homeowners 10% to 20% on heating and cooling costs.

Signs of Worn Weather Stripping

Proper installation is also crucial for the effectiveness of a weather seal. It is important to ensure that the seal is securely attached to the door frame and that there are no gaps or tears that could compromise its performance. In addition to keeping the interior dry, car door window rubber seals also help to reduce noise levels inside the vehicle. By creating a barrier between the door and the window, these seals block out wind and road noise, providing a quieter and more enjoyable driving experience. This is especially important for long trips or highway driving when excessive noise can be tiring and distracting. In addition to preventing air leaks, window edge seal also helps to block out moisture and dust from entering the home. This is particularly important in regions with high humidity levels or frequent rain, as moisture can lead to mold growth and other issues

window edge seal. By creating a tight seal around the window edges, the edge seal helps to keep moisture and dust at bay, ensuring a clean and healthy indoor environment. Protective foam tape is an innovative and versatile solution that has revolutionized the world of packaging, construction, and various manufacturing industries. This specialized tape is designed to provide cushioning, insulation, and protection against impact, vibration, and abrasion, making it an essential tool in numerous applications.

2. Pressure Tolerance Many high temperature applications also involve high pressures. The seal must be designed to resist these pressures to prevent failure.

Benefits of Foam Window Weatherstrip

The Importance of Exterior Weather Stripping for Your Home

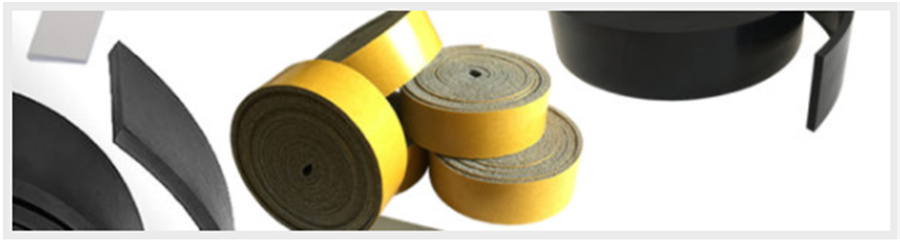

Self-adhesive foam seals have emerged as a crucial component in various industries, owing to their versatility, ease of use, and excellent performance characteristics. These seals are made from high-quality foam materials, often combined with a strong adhesive backing, allowing them to be applied quickly and efficiently. This article explores the key benefits, applications, and considerations associated with self-adhesive foam seals.

The 40mm designation refers to the diameter of the shaft that the seal is designed to fit. This size is commonly used in smaller pumps and machinery, making it a versatile component for various applications. The efficiency of the mechanical seal hinges on the quality of its materials and the precision of its construction. Common materials used include carbon, ceramic, and different types of elastomers, each selected based on the specific fluid being sealed and the operational conditions.

The Importance of a Front Door Threshold Rubber Seal

When compared to the costs associated with repairing dents and scratches, installing door strips is a cost-effective solution for car owners. The relatively low price of these protective strips can save you money in the long run by preventing damage that may require professional repair.

door strips for cars

1. Ease of Use One of the standout features of these rubber strips is their self-adhesive backing, which allows for easy application. Homeowners and builders can simply cut the strip to the desired length, peel off the backing, and press it onto the clean surface. This user-friendly approach minimizes both time and labor costs.

One of the main advantages of expandable foam weatherstrips is their ease of installation. They come in long rolls or strips that can be easily cut to size and fitted into gaps and cracks. Once in place, the foam expands to fill the space, creating a tight seal that helps to keep the interior of the home at a consistent temperature.

6. Test the Door Once installed, open and close the door to ensure that it operates smoothly and that the seal fully engages with the floor.

Component mechanical seals are the most traditional type, consisting of several parts including a rotating component, a stationary component, and sealing faces. This design allows for customization according to the specific demands of the application. Typically made from materials like carbon, ceramic, or silicon carbide, these seals are versatile and can be used in a wide range of conditions. The ability to replace individual parts enhances maintainability and cost-effectiveness, making them a popular choice.

In extrusion molding, the extruder, die and die, as well as the corresponding auxiliary devices are generally selected according to the type and shape of the processed products, and then the extrusion process conditions are determined, such as screw speed, die pressure, setting temperature, etc. In the process of extrusion, the material is usually plasticized, cooled and cured or vulcanized. Different products can be obtained by different extrusion processes.

Installing exterior door weather stripping is relatively easy and can be done with minimal tools. Here's a step-by-step guide

Proper installation is crucial for weather stripping to function effectively. Here are some tips to keep in mind

Foam tape is also widely used in the packaging industry for cushioning delicate items during shipping. Its soft and flexible nature provides excellent protection against impacts and vibrations, reducing the risk of damage during transit. In addition, foam tape is often used to secure packaging materials together, ensuring that items arrive at their destination safely and intact.

Conclusion

In addition to functional benefits, self-adhesive foam strips also contribute aesthetically. They can fill any gaps or irregularities in the window frame, creating a sleek and polished appearance. They are available in various thicknesses and widths, allowing customization to suit different window sizes and requirements.

One of the most significant characteristics of dense foam tape is its ability to absorb shock and vibrations. This property makes it ideal for use in environments where movement or impact is likely, providing a cushioning effect that protects both surfaces and materials. Additionally, dense foam tape can act as an effective insulator against sound, heat, and moisture, further expanding its utility across different applications.

The Versatile Power of Self-Adhesive Flexible Seals

The Importance of Bottom Door Frame Seals Enhancing Home Efficiency and Comfort

5. Install the New Seal Place the new mechanical seal onto the pump shaft, ensuring it is oriented correctly. Follow the manufacturer's specifications for installation, as improper placement can lead to premature failure.

Installing weather stripping seal strips is a simple and cost-effective way to improve the energy efficiency of your home. With just a few tools and some basic DIY skills, you can easily seal gaps and cracks around your doors, windows, and other openings. This can help to reduce your heating and cooling costs, improve indoor comfort, and increase the overall value of your property. - Felt Often used in older vehicles, felt weather stripping is less durable but can be effective for certain applications.

The Importance of 2-Inch Wide Foam Weather Stripping A Comprehensive Guide

Another significant advantage of heavy duty weather stripping is its role in enhancing indoor air quality. By sealing gaps around windows and doors, it prevents dust, pollen, and allergens from entering the home. This is especially beneficial for individuals with allergies or respiratory conditions, as it creates a cleaner and healthier living environment. Furthermore, effective weather stripping can help reduce moisture intrusion, which can lead to mold growth and other related issues.

Moisture and Dirt Barrier

door strip

2. Felt Weather Stripping Felt is typically used in older vehicles and is known for its soft touch and quiet operation. However, it may not provide as robust a seal as rubber and can wear out more quickly, especially in wet conditions.

- Construction In the construction industry, these seals are used to weatherproof windows, doors, and roofing elements. They improve energy efficiency in buildings and protect against external elements.

The Importance of Silicone Foam Seal in Modern Applications

One of the main benefits of an external door seal strip is its ability to improve energy efficiency. By preventing drafts from entering your home, the seal strip helps to keep your living space warm in the winter and cool in the summer. This can lead to significant cost savings on heating and cooling bills over time. 2. Drafts If you can feel cold air seeping in around your windows, it indicates that the seals are not performing their function effectively.

4. Apply Evenly Apply the adhesive evenly across the surface to prevent weak spots. A uniform layer will create a stronger bond.

In construction, self adhesive flexible seal is commonly used to seal gaps between windows and doors, as well as between walls and ceilings. It helps to prevent drafts, moisture, and dust from entering the building, which can improve energy efficiency and indoor air quality. The seal also provides a barrier against noise, helping to create a quieter and more comfortable environment.

1. Functionality of Door Seal Trim

- Material Choose a material that is durable and suited for your climate. For example, rubber seals may be more effective in colder regions, while vinyl may handle warmer climates better.

Thin adhesive foam strips have become an essential tool in various industries due to their versatility and effectiveness. These strips are made of a lightweight and flexible material that can be easily cut, shaped, and attached to different surfaces. The adhesive backing ensures a strong bond, making them ideal for both permanent and temporary applications.

Additionally, the ease of use makes 1-inch foam tape a favorite among professionals and amateurs alike. The tape is available in various thicknesses, adhesion strengths, and even colors, allowing users to select the product that best fits their project requirements. Applying foam tape is straightforward; simply cut it to the desired length and stick it to the surface. Unlike traditional adhesives, there’s no need for drying time, enabling immediate bonding, which can be critical in time-sensitive tasks.

1. Clean the Surface Ensure that the surfaces where the foam will be applied are clean, dry, and free from any debris or old weather stripping material.

In construction, foam strips are used for sealing windows and doors. Their ability to compress allows for a tight seal that blocks air and water infiltration, enhancing energy efficiency within buildings. Architects and builders favor these adhesives because they can accommodate movement and expansion in materials due to temperature changes, which is critical for long-lasting constructions.

When selecting 1% thick foam tape, it’s important to consider the specific requirements of your application. Factors such as adhesive strength, temperature resistance, and the type of surfaces being bonded will influence your choice. Some foam tapes are designed for high-temperature applications, while others may focus on providing a stronger initial tack.

In conclusion, silicone door weather seals represent a smart investment for any homeowner looking to improve comfort, reduce energy costs, and increase property value. Their superior performance and ease of installation make them an ideal solution for safeguarding against unpredictable weather patterns and ensuring a comfortable living environment year-round.