Links:

2. Food Processing The food industry frequently uses ribbed conveyor belts to move food products, such as fruits, vegetables, and baked goods, as the ribs help prevent sliding and maintain hygiene during transport.

When selecting a poly V-belt, factors such as the specific application, load requirements, and environmental conditions must be considered. It is essential to choose a belt that not only matches the size specifications but also meets the durability and performance needs of the application at hand.

What are Variable Speed Belts?

Fordele ved V-bælter

What is a PJ Belt?

2. Low Maintenance Due to their robust construction and resistance to stretching and distortion, poly flat belts require minimal maintenance compared to traditional belts. This not only saves time but also reduces operational costs.

Applications

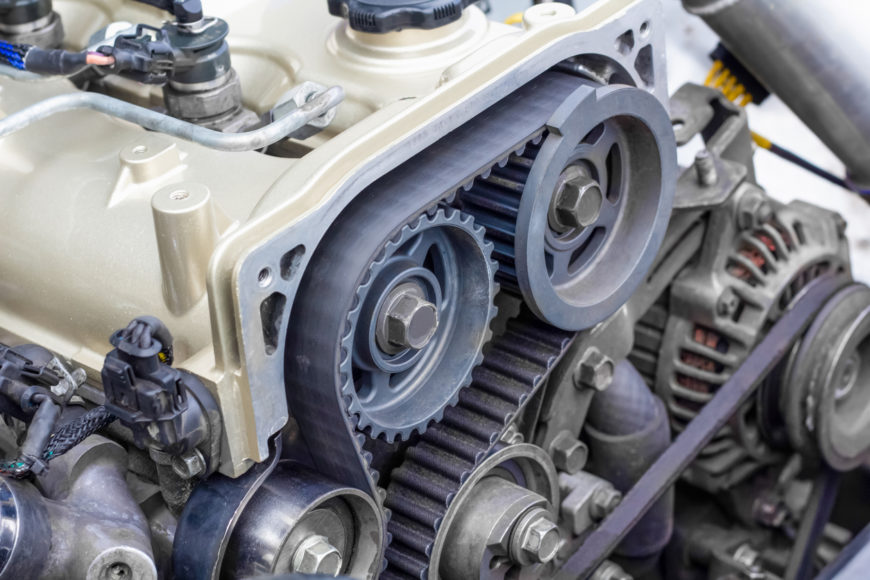

Peugeot vehicles come equipped with manufacturer guidelines regarding when to replace the timing belt. Generally, it’s advisable to replace the timing belt every 60,000 to 100,000 miles, depending on the model and year. However, environmental factors such as extreme temperatures and driving conditions can affect this timeframe.

The Importance of V-Belts in Washing Machines

4. Customization Some automotive applications may require bespoke dynamometer belts tailored to specific performance criteria. Custom belts, because of their unique design and manufacturing requirements, usually carry a higher price tag.

Conclusion

What are EPDM PK Belts?

Understanding the price range and factors affecting the cost of alternator belts is vital for effective vehicle maintenance. Whether you decide to tackle the job yourself or enlist the help of a professional, keeping your alternator belt in good condition will ensure the reliability and performance of your vehicle. Regular inspections and timely replacements can save you from costly repairs and keep your car running smoothly for years to come. Remember, a little prevention goes a long way in automotive care!

3. Improved Technique Proper lifting technique is critical in avoiding injuries and maximizing performance. A power belt encourages lifters to maintain proper posture throughout their movements, which can contribute to better overall biomechanics during lifts.

power belt

Conclusion

4. Replace other Components When replacing an OEM serpentine belt, consider replacing other related components such as the tensioner and idler pulleys. This can enhance belt performance and longevity and reduce the risk of failure.

Conclusion

3. Reduced Noise and Vibration The T10 timing belt operates more quietly than other belt systems, which is a critical factor for manufacturers and consumers alike. Reduced noise and vibration lead to a more pleasant driving experience and lesser mechanical stress on the engine components.

To ensure the optimal performance of your motorbike belt, consider the following maintenance tips

Understanding the V-Ribbed Belt Importance, Applications, and Maintenance

4. Loss of Power Steering A failing belt can also affect the power steering pump, making steering difficult. If steering becomes unusually stiff, it’s advisable to have the fan belt checked.

Konklusion

In conclusion, the belt flat signifies more than just a fashion accessory or a mechanical component. It represents a blend of creativity, practicality, and forward-thinking innovation. As we continue to see the impacts of sustainability and style preferences shape our choices, the belt flat will likely remain a staple, adapting to meet the demands of both fashion enthusiasts and engineers alike. The future looks promising for this versatile and essential element, ensuring that it will continue to play a significant role in various facets of our lives.

- Manufacturing Conveyor systems, mixers, and other machinery in manufacturing facilities often utilize raw edge V-belts due to their reliability and strength.

1. Efficiency Chain drives are generally more efficient than belt systems, with minimal power loss during transmission. This efficiency translates to better acceleration and higher top speeds.

- Material and Construction Look for belts made from breathable materials that allow for airflow, especially during hot riding conditions. The construction should be sturdy yet flexible, allowing for ease of movement without compromising support.

5. Professional Advice If you’re unsure which timing belt to choose, consult with a mechanic. They can recommend reliable brands and options based on your vehicle's needs and performance requirements.

Factors to Consider When Choosing a Timing Belt Supplier

V-belt and pulley systems are essential components in various mechanical applications, playing a crucial role in the transmission of power and motion. These systems are widely utilized in industries ranging from automotive to manufacturing, offering efficiency, reliability, and versatility. This article will explore the mechanics of V-belts and pulleys, their applications, advantages, and maintenance considerations.

3. Textilriemen Häufig in traditionellen Maschinen verwendet, sind sie robust und widerstandsfähig und bieten eine gute Leistung.

In recent years, there has been a growing interest in sustainable fashion, and the Mitsuba Belt fits perfectly into this movement. The emphasis on handmade craftsmanship and the use of natural materials align with modern consumers' desires for eco-friendly products. As people become more aware of the impact of their purchases on the environment, the Mitsuba Belt stands out as a symbol of conscious consumerism, encouraging a shift towards valuing quality over quantity.

A serpentine belt is a long, continuous belt that snakes around multiple pulleys in an engine. This single belt drives several components, including the alternator, power steering pump, water pump, air conditioning compressor, and sometimes even the vehicle’s cooling fan. The design of a serpentine belt allows for a more efficient system compared to older multi-belt setups because it reduces the number of belts and simplifies engine assembly.

3. Better Maintenance Opportunities With savings from discounted belts, vehicle owners can allocate funds to other maintenance needs. Regular maintenance is critical for vehicle longevity, and having extra budget flexibility can ensure that other essential tasks are not overlooked.

Signs of a Failing Timing Belt

5. Variable Speed V-Belts These belts are designed for applications where speed changes are necessary. They can accommodate varying speeds and loads, making them popular in variable speed drives.

Drive belts are essential components in various machines and vehicles, responsible for transferring power from one component to another, most commonly from the engine to other parts like the alternator, water pump, and air conditioning compressor. As with many automotive parts, the price of drive belts can vary significantly based on several factors. In this article, we will explore the key elements that influence drive belt prices, current market trends, and tips for making the best purchasing decisions.

This automatic adjustment is typically a result of a spring-loaded mechanism that maintains tension regardless of temperature fluctuations or belt wear. Some modern vehicles may employ hydraulic tensioners that provide even greater precision in tensioning. Such advances in technology highlight the importance of the fan belt adjuster in maintaining vehicle reliability and performance.

1. Unusual Noises If you hear a slapping noise from the engine, it could indicate that the timing belt is loose or has worn out. This noise might suggest that the belt is not properly aligned with the pulleys.

b18b1 timing belt

1. Material Preparation The raw materials are prepared, which may involve mixing rubber compounds with additives to enhance performance characteristics.

V ribbed belts, often referred to as serpentine belts, are widely used in vehicles and industrial equipment. They can drive multiple components simultaneously, such as alternators, water pumps, and air conditioning compressors. This capability is particularly beneficial in automotive applications, where space is at a premium and multiple drives are required.

Moreover, the advent of the Internet of Things (IoT) has enabled real-time monitoring of vehicle performance, allowing for predictive maintenance and improved reliability. Fleet management systems can track vehicle conditions, facilitating timely repairs and reducing downtime, ultimately leading to greater efficiency for businesses that rely on transportation.

2. Proper Tensioning V-belts should be installed with the appropriate tension. Too loose can lead to slippage, while excessive tension can cause premature wear on the belt and associated components.

The PK belt is a critical component that ensures the proper functioning of various accessories in Renault vehicles. By understanding its importance, recognizing signs of failure, and adhering to maintenance tips, you can enhance the performance and reliability of your car. Regular care of the PK belt not only prevents unexpected breakdowns but also contributes to your vehicle’s overall health, ensuring that you enjoy a smooth and safe driving experience. Always consult your vehicle's owner manual or a certified mechanic if you're unsure about any aspect of your car's maintenance.

3. Suspension Components The suspension system is critical for the comfort and stability of any vehicle. Hino’s advanced suspension parts are designed to absorb shocks effectively and provide a smooth ride even in challenging conditions.

hino auto parts

In the world of mechanical engineering and power transmission, raw edge cogged V-belts play a crucial role in ensuring efficiency and reliability in various applications. These belts are essential components in numerous industries, including automotive, manufacturing, and agriculture. In this article, we will explore the characteristics, benefits, applications, and maintenance of raw edge cogged V-belts.

Exploring the Good Price on PK Belts

- A belt tensioner tool (if necessary)

The serpentine belt is designed to wrap around several pulleys in the engine, creating a continuous loop. Its primary objective is to transfer power from the engine’s crankshaft to the various accessories that require it. This is achieved through the rotation of the crankshaft which, in turn, spins the serpentine belt. The belt's ability to power multiple components simultaneously allows for a more compact engine design, reducing the number of belts required compared to older vehicles that often had multiple V-belts.

Additionally, the manufacturing process often involves testing and quality control measures that adhere to stringent industry standards. These methodologies guarantee that the V-belts used in Japanese vehicles offer optimal performance under a range of conditions, from urban driving to high-speed highway travel.

v belts japan car

Belt drive systems, commonly found in cruiser and touring motorcycles, utilize a durable rubber or composite belt. These systems replace metal links with a continuous loop, offering several benefits