Current location:

Links:

-

In conclusion, understanding the tapered roller bearing number chart is paramount for effective bearing selection. By deciphering these numbers and referring to the chart, one can make informed decisions about the suitability of a bearing for a given task, ensuring optimal performance and longevity in mechanical systems. Always consult the most up-to-date and relevant resources to ensure accurate interpretation and selection of tapered roller bearings.

They might be forced to pass on these increased expenses to their customers or look for alternative suppliers, which could compromise product quality or delay delivery schedules They might be forced to pass on these increased expenses to their customers or look for alternative suppliers, which could compromise product quality or delay delivery schedules

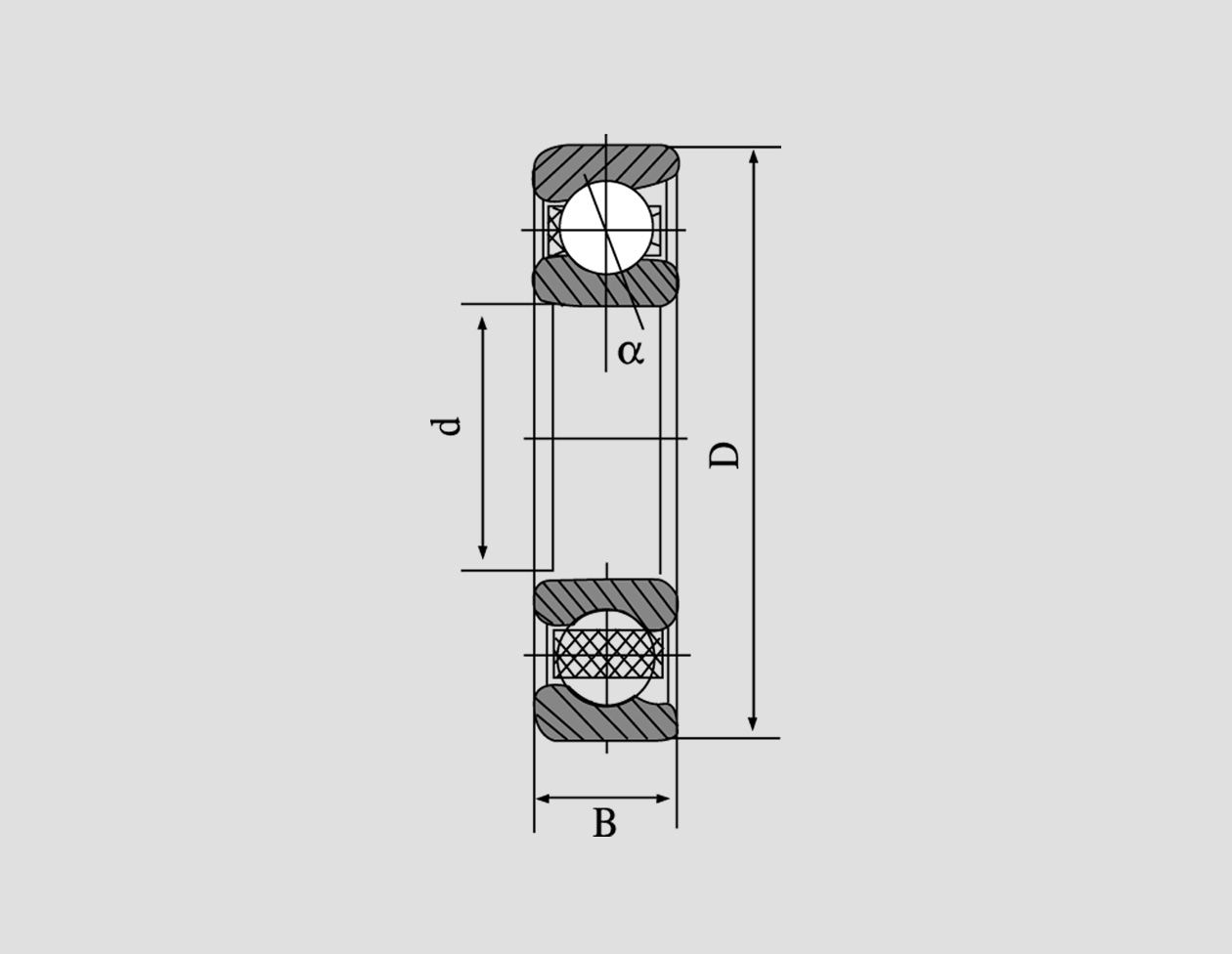

They might be forced to pass on these increased expenses to their customers or look for alternative suppliers, which could compromise product quality or delay delivery schedules They might be forced to pass on these increased expenses to their customers or look for alternative suppliers, which could compromise product quality or delay delivery schedules 22232 bearing price. Moreover, small and medium-sized enterprises (SMEs) that lack the bargaining power of larger corporations might find it difficult to absorb these additional costs, leading to reduced profit margins or even closures. Bearing ID 80 OD 140 taper roller bearings are widely used in various industrial applications due to their excellent load capacity, high reliability, and long service life. These bearings consist of an inner ring, outer ring, tapered rollers, and a cage that keeps the rollers in position. In this article, we will provide a comprehensive guide to help you understand the specifications, selection, installation, maintenance, and troubleshooting of these bearings. The width or thickness of the bearing is also an important dimension to consider, as it affects the load capacity and overall performance of the bearing. The width of the 61800 series bearings varies based on the bore size and can range from 5 mm to 8 mm. This measurement should be taken into account when determining the required space within the assembly and ensuring proper alignment and clearance. Manufacturers have taken notice of these benefits, incorporating the 6312 zz bearing into their products to elevate quality and reliability. As technology continues to evolve, the adaptability and superior function of this bearing make it a cornerstone in the evolution of rotary motion equipment. The ID 80mm signifies the internal diameter of the bearing, which is the dimension that fits onto the shaft it supports. This dimension is crucial for ensuring a secure and precise fit, preventing any unwanted movement or slippage during operation. On the other hand, the OD 140mm denotes the external diameter, determining the overall size of the bearing and the space it will occupy within the machinery. Low-price bearings are those that are offered at a lower cost compared to other bearings within the same category. These bearings are typically manufactured using cost-effective materials and processes, which may result in reduced performance or durability compared to higher-end bearings. However, it is important to note that not all low-price bearings are created equal, and some may still offer satisfactory performance for certain applications. * Aerospace industry Used in aircraft engines, landing gear systems, and other critical components. Role in Advancing Machinery Performance Understanding the Spherical Roller Bearing Size Chart A Comprehensive Guide In the early days, 6210 2RS bearings were primarily made of steel, which provided strength and durability. However, as technology advanced, bearings made of chrome steel were introduced, offering better corrosion resistance and longer life. This advancement was particularly beneficial for applications in harsh environments where exposure to moisture and other corrosive substances was common. Another benefit of taper roller bearings is their ability to accommodate misalignment between the shaft and housing 4. Consult the manufacturer's instructions for specific maintenance and troubleshooting guidelines for your application. However, selecting the right sealed cylindrical roller bearing requires careful consideration of factors such as load capacity, speed rating, operating environment, and maintenance requirements. It is crucial to choose a bearing that can withstand the specific demands of the application to ensure optimal performance and longevity. Thrust angular contact ball bearings are designed to withstand axial loads in one direction. They have a contact angle that allows them to carry these thrust loads efficiently. This design makes them suitable for applications where there is a need to support a heavy axial load in one direction while still allowing for some radial load capacity. Another key advantage of the 51317 bearing is its ability to operate smoothly at high speeds. These bearings are designed with precision raceways and balls that minimize friction and heat generation, allowing them to rotate at high speeds without compromising on performance. This characteristic makes them suitable for use in applications such as turbines, pumps, and compressors, where speed is a critical factor.

22232 bearing price. Moreover, small and medium-sized enterprises (SMEs) that lack the bargaining power of larger corporations might find it difficult to absorb these additional costs, leading to reduced profit margins or even closures. Bearing ID 80 OD 140 taper roller bearings are widely used in various industrial applications due to their excellent load capacity, high reliability, and long service life. These bearings consist of an inner ring, outer ring, tapered rollers, and a cage that keeps the rollers in position. In this article, we will provide a comprehensive guide to help you understand the specifications, selection, installation, maintenance, and troubleshooting of these bearings. The width or thickness of the bearing is also an important dimension to consider, as it affects the load capacity and overall performance of the bearing. The width of the 61800 series bearings varies based on the bore size and can range from 5 mm to 8 mm. This measurement should be taken into account when determining the required space within the assembly and ensuring proper alignment and clearance. Manufacturers have taken notice of these benefits, incorporating the 6312 zz bearing into their products to elevate quality and reliability. As technology continues to evolve, the adaptability and superior function of this bearing make it a cornerstone in the evolution of rotary motion equipment. The ID 80mm signifies the internal diameter of the bearing, which is the dimension that fits onto the shaft it supports. This dimension is crucial for ensuring a secure and precise fit, preventing any unwanted movement or slippage during operation. On the other hand, the OD 140mm denotes the external diameter, determining the overall size of the bearing and the space it will occupy within the machinery. Low-price bearings are those that are offered at a lower cost compared to other bearings within the same category. These bearings are typically manufactured using cost-effective materials and processes, which may result in reduced performance or durability compared to higher-end bearings. However, it is important to note that not all low-price bearings are created equal, and some may still offer satisfactory performance for certain applications. * Aerospace industry Used in aircraft engines, landing gear systems, and other critical components. Role in Advancing Machinery Performance Understanding the Spherical Roller Bearing Size Chart A Comprehensive Guide In the early days, 6210 2RS bearings were primarily made of steel, which provided strength and durability. However, as technology advanced, bearings made of chrome steel were introduced, offering better corrosion resistance and longer life. This advancement was particularly beneficial for applications in harsh environments where exposure to moisture and other corrosive substances was common. Another benefit of taper roller bearings is their ability to accommodate misalignment between the shaft and housing 4. Consult the manufacturer's instructions for specific maintenance and troubleshooting guidelines for your application. However, selecting the right sealed cylindrical roller bearing requires careful consideration of factors such as load capacity, speed rating, operating environment, and maintenance requirements. It is crucial to choose a bearing that can withstand the specific demands of the application to ensure optimal performance and longevity. Thrust angular contact ball bearings are designed to withstand axial loads in one direction. They have a contact angle that allows them to carry these thrust loads efficiently. This design makes them suitable for applications where there is a need to support a heavy axial load in one direction while still allowing for some radial load capacity. Another key advantage of the 51317 bearing is its ability to operate smoothly at high speeds. These bearings are designed with precision raceways and balls that minimize friction and heat generation, allowing them to rotate at high speeds without compromising on performance. This characteristic makes them suitable for use in applications such as turbines, pumps, and compressors, where speed is a critical factor. Bearings are used in a wide range of machines and equipment across various industries. Some common machines that use bearings include:

- Needle Roller Bearings: Needle roller bearings are capable of supporting high radial loads in applications with limited radial space. Their compact design and high load-carrying capacity make them suitable for use in automotive transmissions, small engines, and other machinery with space constraints.

Next, secure the bearing in place using the appropriate fasteners Introduction Maintenance and selection of deep groove ball thrust bearings are critical aspects to consider. Proper lubrication is essential to minimize wear and tear and prolong the bearing's life. Furthermore, choosing the right bearing size and type, considering factors such as load capacity, speed, and operating environment, is crucial for optimal performance. Introduction

Introduction In summary, a cylindrical roller bearing is a critical component in various mechanical systems, providing support for radial loads, high load capacity, rigidity, and precision in a wide range of industrial and commercial applications.

In terms of load capacity, the 6207 ZZ bearing can handle a radial load up to a certain limit, depending on factors like material quality, speed, and operating conditions. Its speed rating is also considerable, allowing it to function effectively in high-speed applications.Moreover, the NJ 307 bearing's design promotes efficient heat dissipation, preventing overheating even under continuous high-speed rotations. The cage material, usually made from high-strength brass or steel, aids in maintaining the uniform spacing of the rolling elements, reducing friction and noise during operation. Our angular contact ball bearings are designed to provide high speed and load capacity in a compact package. They feature a unique design that allows them to accommodate both radial and axial loads simultaneously. This makes them ideal for applications such as pumps, fans, and gearboxes.

One of the key advantages of four-row taper roller bearings is their ability to support both radial and axial loads simultaneously. This dual capability makes them ideal for applications where both types of forces are present, such as gearboxes, wind turbines, and heavy equipment. Traditional bearings, on the other hand, are typically limited to supporting either radial or axial loads, which can lead to premature failure in complex operating environments. The 6002zz bearing is also known for its high speed capabilities, making it ideal for applications where rapid rotation is necessary. Its low friction design helps to reduce heat and energy loss, improving the overall efficiency of the system. The 6321 bearing is a popular choice among engineers and manufacturers due to its reliability, durability, and ability to withstand high loads. This article provides a comprehensive guide to the dimensions of the 6321 bearing, including its inner diameter, outer diameter, width, and other critical specifications. Understanding these dimensions is essential for selecting the right bearing for your specific application and ensuring optimal performance. 3. Inspection Regularly inspect the bearing for signs of wear, damage, or misalignment. Specifications of the 6302 Bearing 4. Environmental sustainability The 25877 bearing's low friction properties lead to reduced energy consumption, making it an environmentally friendly alternative to traditional bearings. 1. Standard bearings These bearings have a standard internal diameter, width, and cage design. The ID taper ratio, another critical aspect, determines the bearing's load distribution and performance

3 4 id tapered roller bearing. A higher taper ratio signifies a steeper angle between the roller and the inner ring, leading to increased thrust loading capacity. In the case of the 3 4 ID Tapered Roller Bearing, the specific taper ratio would be specified by the manufacturer, dictating its specific load-bearing characteristics. One of the key advantages of taper roller bearings is their ability to accommodate misalignment. The tapered rollers allow the bearing to self-align and maintain its proper operating position even when subjected to misalignment or shock loads. This makes them particularly well-suited for use in machinery where alignment is critical, such as gearboxes, pumps, and turbines.

3 4 id tapered roller bearing. A higher taper ratio signifies a steeper angle between the roller and the inner ring, leading to increased thrust loading capacity. In the case of the 3 4 ID Tapered Roller Bearing, the specific taper ratio would be specified by the manufacturer, dictating its specific load-bearing characteristics. One of the key advantages of taper roller bearings is their ability to accommodate misalignment. The tapered rollers allow the bearing to self-align and maintain its proper operating position even when subjected to misalignment or shock loads. This makes them particularly well-suited for use in machinery where alignment is critical, such as gearboxes, pumps, and turbines.