Links:

-

Different types of heavy duty sewing needles exist, each tailored for specific tasks. For instance, the jeans needle, also known as the denim needle, is a popular choice for sewing through multiple layers of thick fabric For instance, the jeans needle, also known as the denim needle, is a popular choice for sewing through multiple layers of thick fabric

For instance, the jeans needle, also known as the denim needle, is a popular choice for sewing through multiple layers of thick fabric For instance, the jeans needle, also known as the denim needle, is a popular choice for sewing through multiple layers of thick fabric

For instance, the jeans needle, also known as the denim needle, is a popular choice for sewing through multiple layers of thick fabric For instance, the jeans needle, also known as the denim needle, is a popular choice for sewing through multiple layers of thick fabric heavy duty sewing needle. The universal needle, on the other hand, is versatile and can handle a range of fabrics, including some heavy-duty ones.

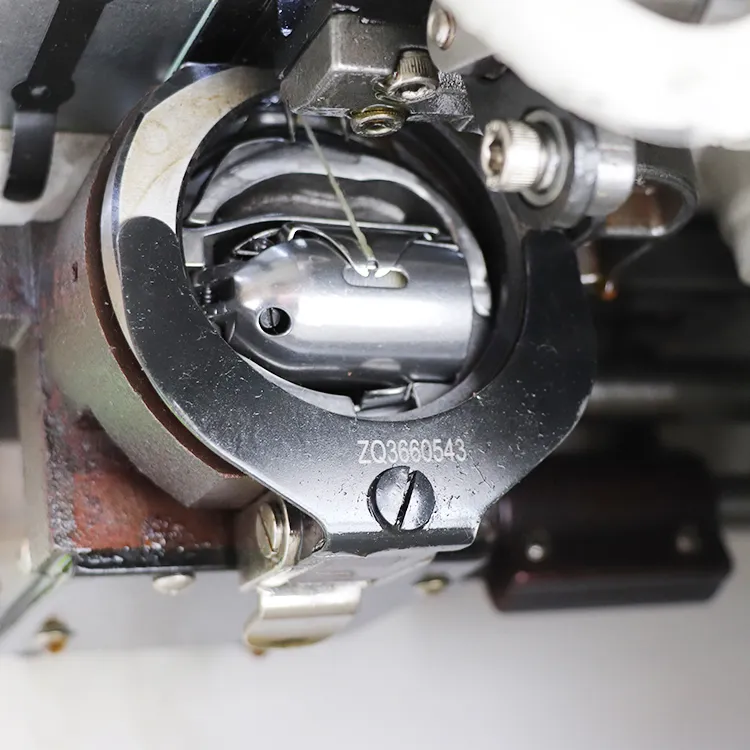

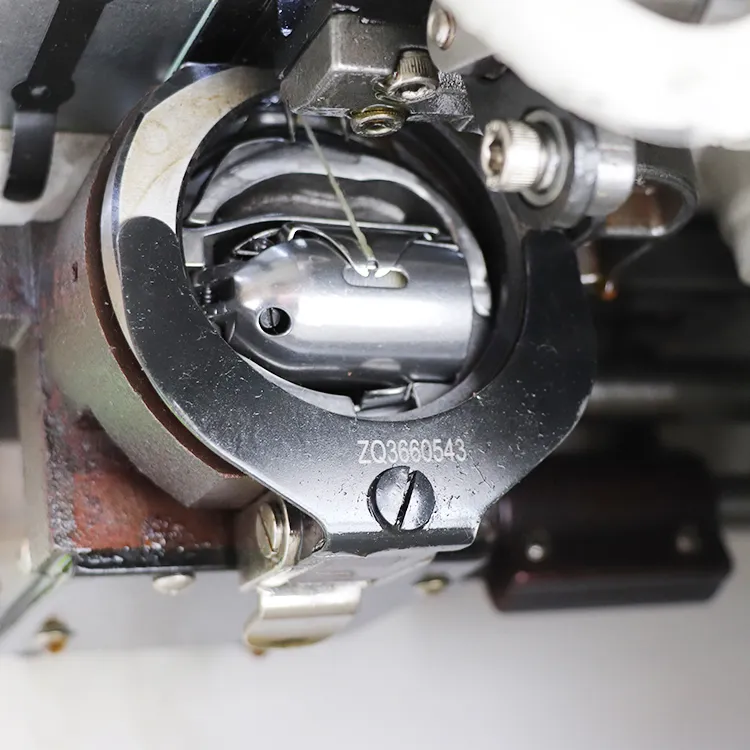

heavy duty sewing needle. The universal needle, on the other hand, is versatile and can handle a range of fabrics, including some heavy-duty ones. Maintenance and Care for Heavy Duty Sewing Machines

This thing is heavy – weighing close to 40 lbs! So you definitely don’t have to worry about it walking around on you.

The Versatility and Benefits of Two Needle Embroidery Machines