2. Automotive Use Car enthusiasts often keep Black Flex Tape in their repair kits. It can be used to fix things like windshield leaks, sealing gaps in the bodywork, or even temporarily repairing hoses and wires.

Shouldn’t snap when you wrap.

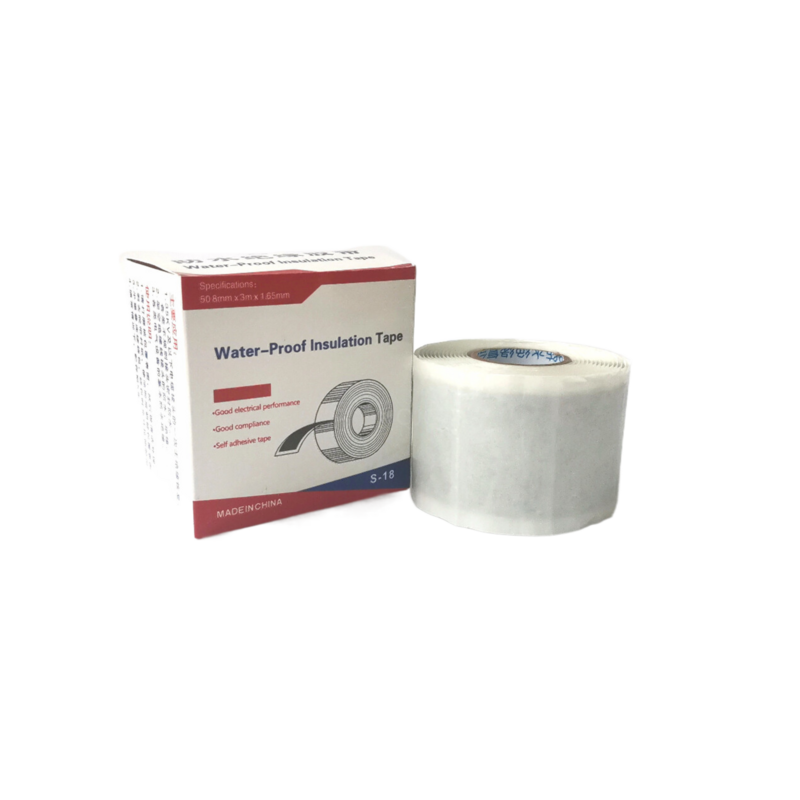

The durability of Seal It Silicone Insulation Tape is another notable feature. It is UV resistant, preventing degradation from prolonged exposure to sunlight. Additionally, it is resistant to chemicals, moisture, and abrasion, ensuring a long-lasting seal that maintains its integrity over time.Polyethylene Rubber Tape is composed of a polyethylene backing material with a rubber-based adhesive. Polyethylene is a thermoplastic polymer known for its excellent resistance to moisture, chemicals, and abrasion. The rubber adhesive provides strong adhesion to different surfaces.

In conclusion, gray electrical tape is more than just a utilitarian roll of sticky backing; it's a vital component in the toolkit of any do-it-yourself enthusiast or professional electrician. Its reliability, versatility, and understated color make it an indispensable resource, proving that sometimes the most effective tools are those that blend into the background, working diligently without seeking fanfare.In electrical applications, white PVC insulation tape is often used for insulating wires and cables. It helps to prevent electrical shorts and protects against moisture, which can lead to corrosion and system failure. Whether encasing a repair or bundling multiple wires together, this tape ensures that connections remain safe and operational.

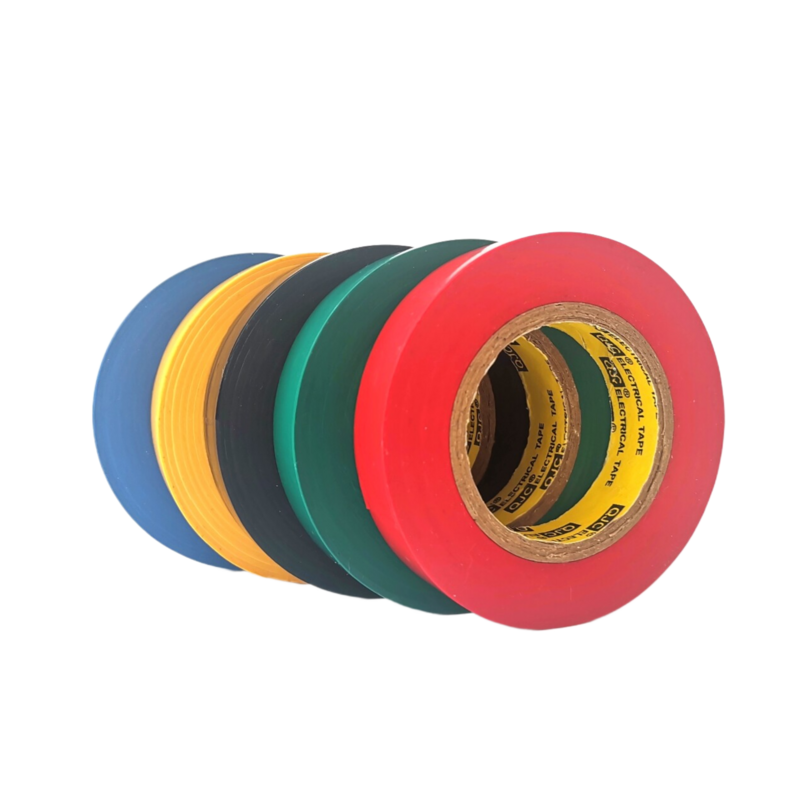

PVC electrical tape and vinyl electrical tape are the two main types of cold-weather tape used for insulating wiring. The conditions in which they will be used may dictate which type you use as follows:

In conclusion, flame retardant tapes are an essential tool across a myriad of industries, offering critical benefits in terms of safety, compliance, and versatility. As technology advances and industries continue to emphasize fire safety, the role of these tapes will undoubtedly expand. Their ability to provide reliable flame resistance while being easy to apply makes them an invaluable asset, ensuring that both industrial and consumer products meet the highest safety standards. Whether in manufacturing, construction, or everyday consumer goods, flame retardant tapes are a shining example of innovation in safety technology, aimed at protecting both people and property from the devastating effects of fire.

1. Prepare the surface Before applying the tape, make sure the surface is clean and dry. Remove any dirt, grease, or debris from the surface to ensure a proper seal.

By using tape to secure the wiring loom in place, it helps to minimize the risk of damage and prolong the life of the electrical system By using tape to secure the wiring loom in place, it helps to minimize the risk of damage and prolong the life of the electrical system

By using tape to secure the wiring loom in place, it helps to minimize the risk of damage and prolong the life of the electrical system By using tape to secure the wiring loom in place, it helps to minimize the risk of damage and prolong the life of the electrical system car wiring loom tape. In addition to its primary use in electrical insulation, rubber insulation tape finds applications in other industries too One of the advantages of using rubber tape to stop water leaks is its flexibility. Rubber tape can conform to any shape or surface, making it ideal for sealing leaks in hard-to-reach places. It is also resistant to extreme temperatures and weather conditions, ensuring a long-lasting and reliable seal. In conclusion, the choice of PVC insulation tape manufacturer can significantly impact the quality of the product you receive and the overall satisfaction with your purchase. By focusing on a manufacturer's reputation, product range, customer service, and environmental practices, you can navigate the market with confidence and select a supplier that meets your specific needs. Remember, a little research can go a long way in ensuring that your PVC insulation tape performs as expected, under even the most demanding conditions. The Indispensable Role of Fireproof Adhesive Tape in Modern Safety Measures In conclusion, the Arc Proof Tape is a testament to the ongoing advancements in electrical safety technology. Its introduction has ushered in a new era of protection, reliability, and efficiency in the face of potentially devastating arc flash incidents. As we continue to push the boundaries of innovation, the Arc Proof Tape stands as a symbol of our commitment to safeguarding lives and infrastructure in the electrical domain. Step 6 Smooth Out the Tape The application of scotch self-amalgamating tape extends far beyond basic repairs

car wiring loom tape. In addition to its primary use in electrical insulation, rubber insulation tape finds applications in other industries too One of the advantages of using rubber tape to stop water leaks is its flexibility. Rubber tape can conform to any shape or surface, making it ideal for sealing leaks in hard-to-reach places. It is also resistant to extreme temperatures and weather conditions, ensuring a long-lasting and reliable seal. In conclusion, the choice of PVC insulation tape manufacturer can significantly impact the quality of the product you receive and the overall satisfaction with your purchase. By focusing on a manufacturer's reputation, product range, customer service, and environmental practices, you can navigate the market with confidence and select a supplier that meets your specific needs. Remember, a little research can go a long way in ensuring that your PVC insulation tape performs as expected, under even the most demanding conditions. The Indispensable Role of Fireproof Adhesive Tape in Modern Safety Measures In conclusion, the Arc Proof Tape is a testament to the ongoing advancements in electrical safety technology. Its introduction has ushered in a new era of protection, reliability, and efficiency in the face of potentially devastating arc flash incidents. As we continue to push the boundaries of innovation, the Arc Proof Tape stands as a symbol of our commitment to safeguarding lives and infrastructure in the electrical domain. Step 6 Smooth Out the Tape The application of scotch self-amalgamating tape extends far beyond basic repairs 2. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, fire-resistant adhesive tape can be used to seal ductwork and other components to prevent the spread of fire.

2. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, fire-resistant adhesive tape can be used to seal ductwork and other components to prevent the spread of fire. Conclusion

This is especially important for homes located in areas with high levels of precipitation or near bodies of water This is especially important for homes located in areas with high levels of precipitation or near bodies of water

This is especially important for homes located in areas with high levels of precipitation or near bodies of water This is especially important for homes located in areas with high levels of precipitation or near bodies of water waterproof door seal strip. In the world of DIY repairs, Flex Tape has become a household name for its versatility and strength. Now, with the release of Flex Tape in white, this innovative product is taking the market by storm.

waterproof door seal strip. In the world of DIY repairs, Flex Tape has become a household name for its versatility and strength. Now, with the release of Flex Tape in white, this innovative product is taking the market by storm. 1. Inspect the Area Check for any gaps around doors and windows. A simple test is to close a door or window and see if light passes through; if it does, weather stripping is needed.

Used for insulation and cable management, it can withstand extreme temperatures and harsh conditions encountered in space travel Used for insulation and cable management, it can withstand extreme temperatures and harsh conditions encountered in space travel

Used for insulation and cable management, it can withstand extreme temperatures and harsh conditions encountered in space travel Used for insulation and cable management, it can withstand extreme temperatures and harsh conditions encountered in space travel self annealing tape. The tape's self-repairing nature ensures the integrity of critical systems, enhancing overall safety.

self annealing tape. The tape's self-repairing nature ensures the integrity of critical systems, enhancing overall safety. Whether you need to insulate a wire or secure loose wiring, electrical tape is up for the task. Just be sure to choose the right size and thickness for your project, and you’ll be good to go!