Links:

Partnerships and collaboration are also key aspects of being an effective window seal rubber strip manufacturer. Building solid relationships with suppliers, distributors, and contractors can enhance product visibility and accessibility. Additionally, investing in research and development will drive innovation and result in new and improved products that meet the ever-evolving demands of the market.

.

Neon LED lights are a modern reinterpretation of classic neon signs, which have long been beloved for their vibrant glow and eye-catching designs. The fundamental difference lies in the technology used for illumination. Traditional neon signs involve gas-filled glass tubes that require high voltages to create light, while LED technology utilizes semiconductor diodes to produce light through electroluminescence. This not only makes LED lights more energy-efficient but also allows for greater design flexibility, with options for different colors, shapes, and sizes.

The process of creating handmade ABS strips often involves artisanal techniques that highlight the material's characteristics. Artisans can manipulate the strips to create intricate designs, allowing for personalization that mass-produced items cannot offer. These strips can be dyed in a variety of colors and patterns, making them perfect for decorative purposes or artistic projects. As consumers increasingly seek products that tell a story, the handcrafted nature of these strips adds value and allure.

ce cetification abs strips hand made

Types of Bath Seal Strips

Conclusion

- Quantity Bulk orders often qualify for discounts, making it essential to assess your project's needs carefully.

CE Certification Process for Sliding Door Strip Seals

Easy Installation and Maintenance

In addition to traditional manufacturing techniques, exporters are continually innovating in their production processes. Many are adopting environmentally friendly practices, such as using recycled plastics and developing biodegradable options. This commitment to sustainability is not only attractive to international buyers but is also becoming a requirement as consumers increasingly prefer eco-friendly products.

square plastic tube exporter

4. Energy Efficiency If your wardrobe is placed near a window or an exterior wall, using seal strips can help prevent drafts. This contributes to better energy efficiency in your home, allowing you to maintain a comfortable temperature without overworking your heating or cooling systems.

Moreover, a diverse range of products to cater to different wardrobe styles and designs is essential. Whether you have sliding doors, folding doors, or traditional hinged wardrobes, the seal strips should be adaptable to various configurations. The company should also provide options in various colors and textures to complement the aesthetic of your wardrobe and overall decor.

5. Installation Costs

Conclusion

Top Picks for the Best LED Neon Rope Lights

In the modern world, the demand for illuminated advertising and display solutions has surged. One of the key components in creating effective light boxes is the use of fabric edge PVC strips. These strips not only enhance the aesthetic appeal of light boxes but also contribute to their functionality and durability. This article explores the manufacturing process, benefits, and future trends of light box fabric edge PVC strips.

Single edge aluminum manufacturers play a critical role in the production and supply of these specialized aluminum products. They employ advanced manufacturing processes that ensure high precision and quality in the final product. Here are some key aspects of their role

Door seal strip prices can vary significantly based on factors such as the make and model of the vehicle, the type of seal strip needed, and whether it's a direct OEM replacement or an aftermarket option. Generally, you can expect prices to range from around $20 to $100 or more. For instance, a standard generic door seal might cost approximately $20, while a specific OEM part for a luxury vehicle could reach upwards of $100. Additionally, it’s a good idea to keep an eye out for seasonal sales or promotions, which can make these necessary purchases even more affordable.

Key Features of Quality Magnetic Seal Strips

Energy Efficiency

1. Excellent Compressibility Sponge rubber seals can compress significantly under pressure, adapting to the surface they are sealing against. This property ensures a reliable seal, which is crucial in preventing leaks in various industrial equipment.

Bath tub seal strips are designed to provide a watertight seal between the bathtub and the wall or floor. They are typically made from durable materials such as silicone, rubber, or PVC and serve multiple purposes, including preventing water leakage, reducing mildew growth, and enhancing the overall look of the bathroom. Choosing an OEM bath tub seal strip guarantees compatibility with the specific model of the bathtub and ensures that the product meets the manufacturer’s standards.

Benefits of Using Adhesive Bath Seal Strips

Benefits of RGB Flex Neon LED Strip Lights

7. Packaging and Distribution Once approved, the strips are packaged for shipping to wholesalers, retailers, and manufacturers who will use them in window production. Proper packaging ensures that the seals remain in top condition during transportation.

What is CE Certification?

Sealing, on the other hand, involves securely closing a package to prevent the entry of moisture, air, or contaminants. Custom vinyl seals can be tailored to fit various shapes and sizes, providing an effective barrier that keeps the product intact and safe from tampering. This combination of stripping and sealing grants manufacturers the ability to customize their packaging to meet specific market demands.

1. Weather Protection

In summary, glass door side seal strip manufacturers are essential players in the construction and design industry, providing critical components that enhance the performance, efficiency, and aesthetics of glass doors. By prioritizing quality, customization, and sustainability, these manufacturers contribute to the long-term success of glass door installations while meeting the evolving demands of consumers. For anyone involved in construction, renovation, or design, understanding the importance of working with a reputable manufacturer can lead to superior results and lasting value.

3. Aesthetic Appeal Apart from functionality, seal strips enhance the overall aesthetic of a kitchen. They provide a finished look by covering unsightly gaps and seams, contributing to a sleek and polished appearance.

ce cetification kitchen worktop seal strip

4. Weather Resistance Look for products that are weather-resistant to ensure longevity, especially if you live in an area with extreme conditions. UV protection and water resistance are essential features.

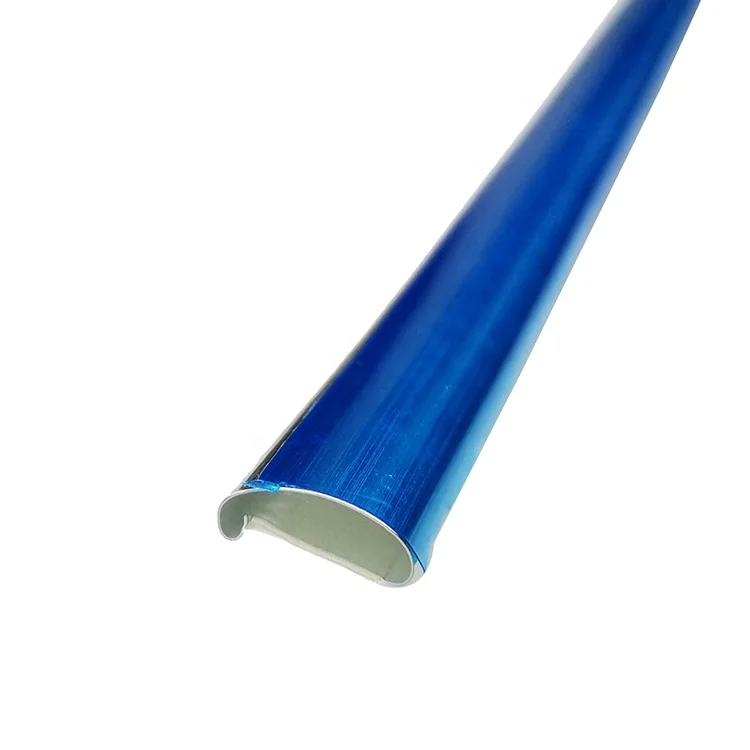

best car chrome moulding trim strip

The Growing Demand for Door Seal Strips

When it comes to sourcing shower door water seal strips, selecting a reputable manufacturer is essential. Here are some criteria to consider

Tools and Materials Needed

Why Choose Aluminum?

- Brand Reputation Research manufacturers and read reviews to ensure you are purchasing from a reputable factory known for quality products.

When selecting the right rubber weather seal strip, consider the following

4. Installation Chrome moulding trim strips are often designed for easy installation, requiring minimal tools. Many automotive service providers in India offer installation services, making it even more accessible for car owners.

2. Include Key Details Ensure that all relevant information is included, such as product specifications, timelines, quality requirements, and payment terms. Every detail counts, as these will define the partnership's success.

In addition to their thermal insulation capabilities, silicone foam seal strips serve as excellent soundproofing solutions. They can absorb sound waves and reduce noise transmission, which is essential for creating a peaceful indoor environment. This is particularly beneficial in settings like apartments, offices, and other shared spaces where noise pollution can be intrusive.

Selecting the right side light materials, particularly between the 6mm and 8mm options, involves careful consideration of numerous factors, including application, durability, and budgetary constraints. High-quality materials can not only enhance the aesthetic appeal of a space but also improve functionality and longevity. By understanding the advantages of each thickness, designers and homeowners can make informed decisions that effectively illuminate their spaces while meeting their unique needs. Whether you opt for the lightweight and versatile 6mm or the robust and reliable 8mm, investing in quality side light material is essential for achieving a successful lighting design.

Moreover, cutting-edge recycling technologies are now enabling aluminum coil factories to incorporate recycled aluminum into their production processes. This not only reduces the carbon footprint associated with mining and processing virgin materials but also makes use of the significant amount of scrap aluminum generated in various industries.

3. Customization Manufacturers offering EPDM sponge seals often provide customization options regarding thickness, density, and size, ensuring that specific requirements are met for varied applications.

- Innovative Designs The Chinese market is known for its innovative approaches to common problems. Many manufacturers are continually improving their products to enhance effectiveness and ease of installation. For instance, some seal strips come with adhesive backing for straightforward installation, while others offer interlocking designs for high-performance sealing.

2. Customization Capabilities The ability to provide customized solutions is essential for suppliers in this niche market. Clients often require specific dimensions, shapes, and properties for their applications, and suppliers must be equipped to offer tailored solutions.

Looking ahead, the future for LED neon wall light exporters appears bright. The combination of ongoing technological advancements and changing consumer preferences will continue to shape the industry. Innovations such as smart lighting features, where neon lights can be controlled via smartphone apps, are expected to attract tech-savvy customers. Additionally, as urban living spaces become smaller, the demand for compact and multifunctional lighting solutions is likely to increase.

At the core of Seal King Strip All’s mission is the development of high-performance sealing products that cater to various industrial needs. Historically, factories have relied on traditional methods for sealing and insulation, which often involved materials that are not only inefficient but also environmentally damaging. Seal King Strip All recognizes these challenges and has set out to provide solutions that not only enhance operational efficiency but also minimize environmental impact.

The manufacturing process for high-quality rubber sealing strips typically involves rigorous quality control measures. This includes testing for tensile strength, elongation, and compression set, as well as exposure to extreme temperatures and chemicals. These tests ensure that the final product meets the exacting standards required for various applications, thereby providing peace of mind to manufacturers and end-users alike.

In an age where sustainability is a priority for many homeowners, opting for custom wooden door seal strips can also contribute to eco-friendly living. Sourced from sustainably managed forests, wooden products have a lower environmental impact compared to synthetic materials. This choice not only supports responsible forestry practices but also helps reduce the carbon footprint associated with manufacturing plastic or synthetic alternatives.

Additionally, online platforms often showcase promotional offers, bulk discount options, or clearance sales. Many offer transparent price listings, allowing customers to compare prices effectively and select products that fit their budget.