Links:

-

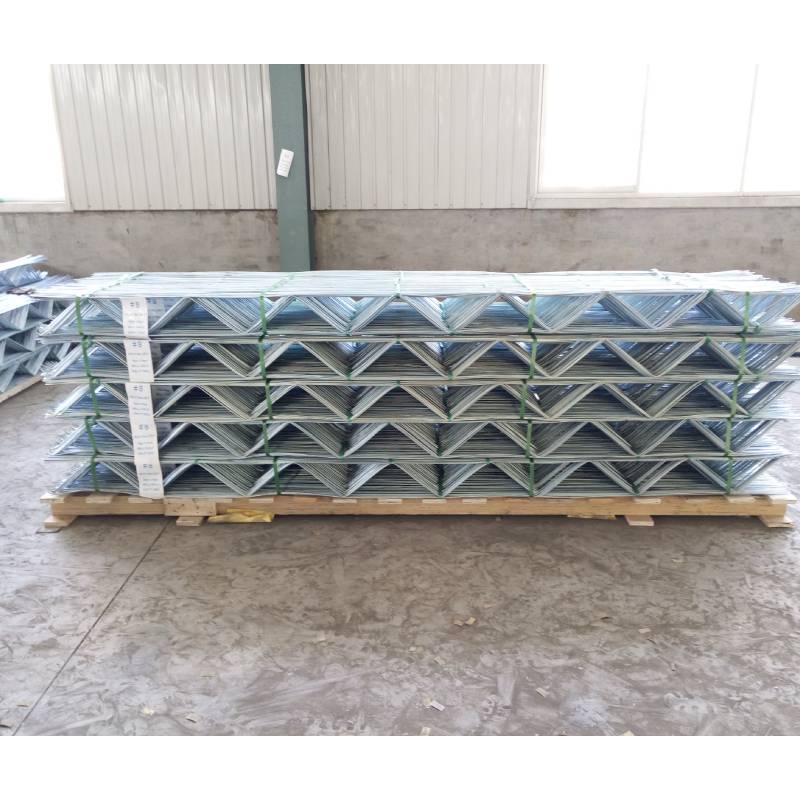

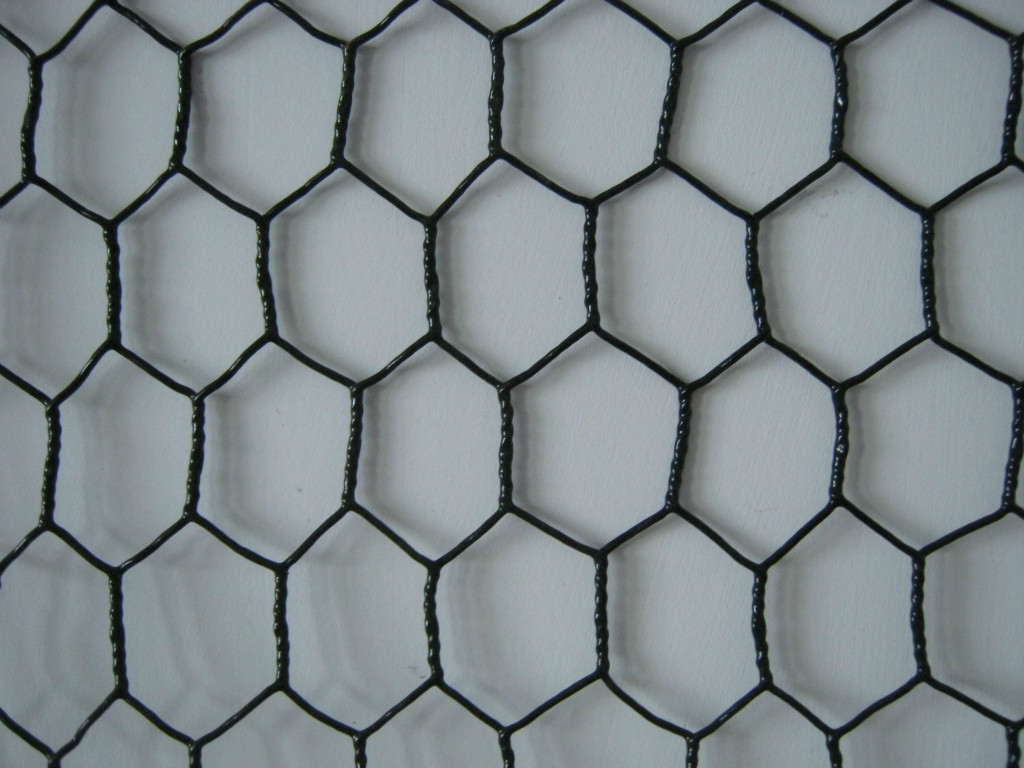

Stucco wire, a versatile and essential material in construction, is used for a variety of purposes. It is a type of steel reinforcement that is encased in a stucco coating, providing strength and durability to the structure it reinforces. Stucco wire is commonly used in the construction of walls, ceilings, and other load-bearing elements in residential and commercial buildings. Galvanized wire is a type of steel wire that has been coated with a layer of zinc to prevent rust and corrosion. This process, known as galvanization, helps to extend the lifespan of the wire and make it more resistant to harsh environmental conditions. Overall, black wire panels are a stylish and practical choice for those looking to enhance the look of their space. Whether used as a decorative element or as a functional partition, these panels offer a range of benefits that make them a popular choice for interior designers and homeowners alike. With their sleek design, durable construction, and versatile applications, black wire panels are sure to add a touch of sophistication to any room. One of the primary advantages of PVC coated galvanized wire is its durability. The zinc coating prevents rust and corrosion, ensuring that the wire remains in good condition for an extended period. The PVC coating further enhances the wire's durability by protecting it from environmental factors such as rain, snow, and extreme temperatures. As a result, PVC coated galvanized wire is ideal for use in outdoor environments where it is exposed to the elements. Galvanized steel chicken wire is not just a mere physical barrier; it is a testament to human ingenuity and our ongoing quest for harmony with our surroundings. The process of galvanization involves coating the steel wire with a protective layer of zinc, effectively shielding it from rust and corrosion. This ensures that the wire can withstand the harsh elements, providing a longer service life compared to its untreated counterparts.

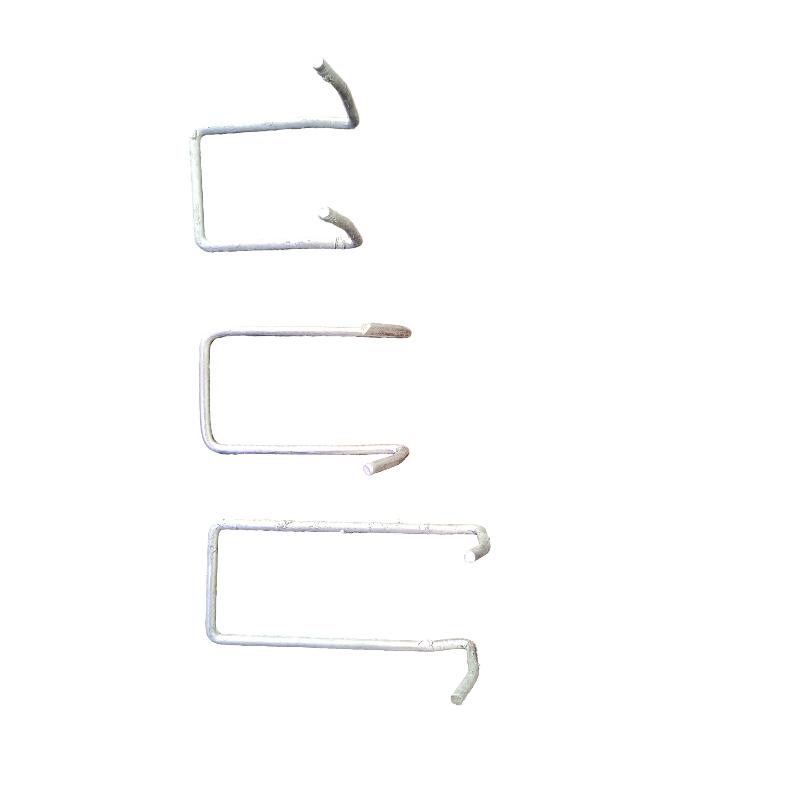

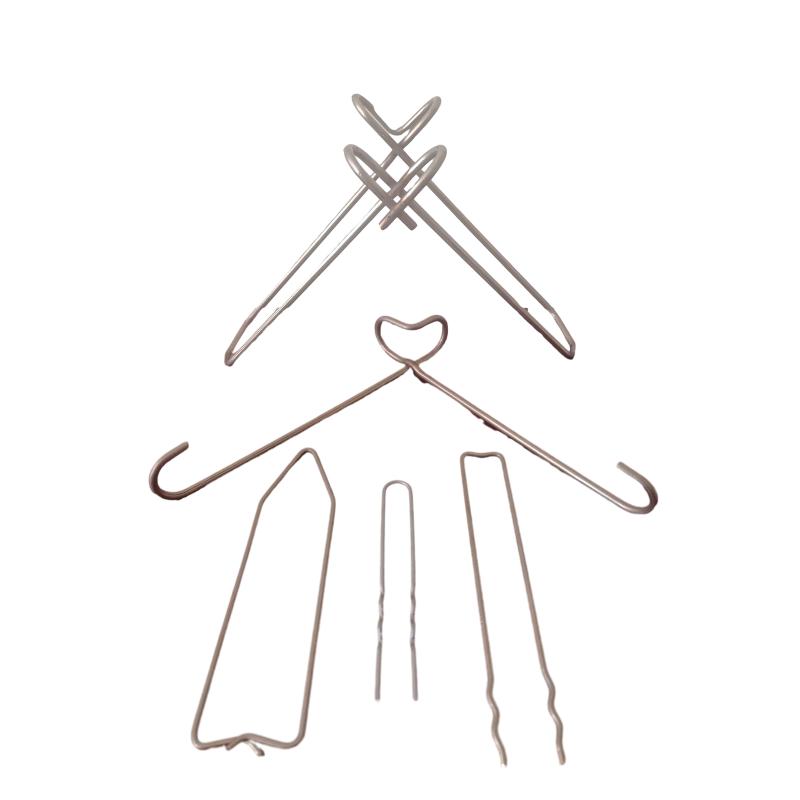

When installing 250mm brick ties, it is important to follow the manufacturer's instructions and ensure proper alignment and spacing. Additionally, regular inspections and maintenance of the brick ties are essential to ensure their effectiveness and prevent any potential issues.

Firstly, we have the woven wire fence, also known as a 'welded wire' or 'field fence.' This type is made by weaving steel wires together, creating a strong and durable barrier. It's popular for its ability to keep animals contained while allowing visibility through the fence. The spacing between wires varies, with smaller gaps suitable for containing smaller animals like sheep or goats, while larger gaps work well for larger livestock like cattle. Another critical factor in wire mesh quality is the choice of materials. Stainless steel is a popular choice due to its resistance to corrosion and longevity. However, depending on the specific application, other materials such as Galvanized steel or Black wire may be more appropriate. The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced

The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced

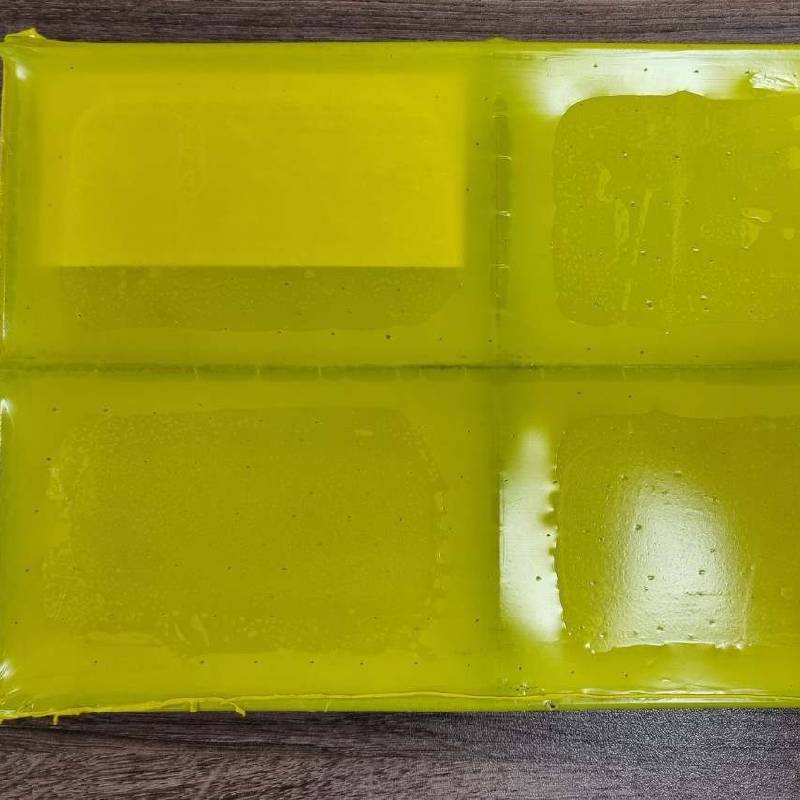

The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced reinforcement wire mesh size. The primary function of horizontal joint reinforcement is to resist crack propagation and maintain the structural continuity of the masonry. When a masonry wall is subjected to lateral forces, it tends to develop diagonal cracks due to the difference in compression and tension stresses. The reinforcing steel provides a tensile force that counteracts these stresses, reducing the likelihood of crack formation and preventing any potential structural failure. In addition to their durability, stainless compression springs are also highly resistant to corrosion. This is particularly important for applications in which the springs will be exposed to moisture or chemicals. By using stainless steel, manufacturers can ensure that their springs will maintain their strength and performance even in harsh environments. As the sun rises over sprawling ranchlands, the importance of wholesale cattle fence becomes as clear as the morning sky. This unsung hero of modern ranching plays a pivotal role in ensuring the safety and health of livestock, while also streamlining operations for farmers and ranchers alike. Electric fencing is another option that has gained popularity for its efficiency in containing cattle with minimal structure. While the initial investment in the energizer and insulated wires may be higher, the lower cost of maintenance and the flexibility to move the fence make it an economical choice for rotational grazing systems. Additionally, electric fences can deter predators, adding an extra layer of protection for your herd Additionally, electric fences can deter predators, adding an extra layer of protection for your herd

reinforcement wire mesh size. The primary function of horizontal joint reinforcement is to resist crack propagation and maintain the structural continuity of the masonry. When a masonry wall is subjected to lateral forces, it tends to develop diagonal cracks due to the difference in compression and tension stresses. The reinforcing steel provides a tensile force that counteracts these stresses, reducing the likelihood of crack formation and preventing any potential structural failure. In addition to their durability, stainless compression springs are also highly resistant to corrosion. This is particularly important for applications in which the springs will be exposed to moisture or chemicals. By using stainless steel, manufacturers can ensure that their springs will maintain their strength and performance even in harsh environments. As the sun rises over sprawling ranchlands, the importance of wholesale cattle fence becomes as clear as the morning sky. This unsung hero of modern ranching plays a pivotal role in ensuring the safety and health of livestock, while also streamlining operations for farmers and ranchers alike. Electric fencing is another option that has gained popularity for its efficiency in containing cattle with minimal structure. While the initial investment in the energizer and insulated wires may be higher, the lower cost of maintenance and the flexibility to move the fence make it an economical choice for rotational grazing systems. Additionally, electric fences can deter predators, adding an extra layer of protection for your herd Additionally, electric fences can deter predators, adding an extra layer of protection for your herd Additionally, electric fences can deter predators, adding an extra layer of protection for your herd Additionally, electric fences can deter predators, adding an extra layer of protection for your herd

Additionally, electric fences can deter predators, adding an extra layer of protection for your herd Additionally, electric fences can deter predators, adding an extra layer of protection for your herd cattle fence cost per foot.

cattle fence cost per foot. In manufacturing and fabrication processes, galvanized iron wire is used in a multitude of applications, from assembling machinery and equipment to fabricating industrial components. The wire's versatility allows it to be formed into custom shapes and configurations to meet specific manufacturing requirements. Whether used as reinforcement in composite materials, support for ductwork and piping systems, or as a fastening component in assembly lines, galvanized iron wire provides a cost-effective and reliable solution for a wide range of industrial needs. Its resistance to corrosion ensures that manufactured products maintain their integrity and functionality, even in demanding industrial environments.

Innovations in materials science have also influenced the development of heavy duty brick ties heavy duty brick ties. Stainless steel versions, for example, offer excellent corrosion resistance, essential in coastal areas or environments with high humidity. Similarly, ties coated with polymers can provide additional protection against elements, reducing maintenance needs and extending the lifespan of the structure.

heavy duty brick ties. Stainless steel versions, for example, offer excellent corrosion resistance, essential in coastal areas or environments with high humidity. Similarly, ties coated with polymers can provide additional protection against elements, reducing maintenance needs and extending the lifespan of the structure. Industrial wires, often designed for specific applications, are another area of expertise for these suppliers. They cater to industries like automotive, aerospace, construction, and renewable energy, with products like welding wires, control cables, and high-temperature resistant wires. Furthermore, custom cable solutions are available for unique requirements, ensuring a tailored fit for clients' needs Furthermore, custom cable solutions are available for unique requirements, ensuring a tailored fit for clients' needs

Furthermore, custom cable solutions are available for unique requirements, ensuring a tailored fit for clients' needs Furthermore, custom cable solutions are available for unique requirements, ensuring a tailored fit for clients' needs

Furthermore, custom cable solutions are available for unique requirements, ensuring a tailored fit for clients' needs Furthermore, custom cable solutions are available for unique requirements, ensuring a tailored fit for clients' needs gi wire suppliers. The choice of fence height is not just about security; it's also influenced by zoning laws and homeowner association regulations. It's crucial to check local guidelines before installation, as there might be restrictions on fence heights to maintain visual harmony and prevent obstruction of views. The history of copper craft wire dates back to ancient civilizations where it was used for practical purposes, such as jewelry making and architectural embellishments. Over time, it evolved into a form of artistic expression, reflecting cultural narratives and personal stories. From the elaborate Celtic knotwork to the delicate Native American designs, copper wire has been a universal symbol of creativity and craftsmanship. Another significant advantage of bulk extension springs is their compact design The process of joint reinforcement involves careful planning and execution. Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction

gi wire suppliers. The choice of fence height is not just about security; it's also influenced by zoning laws and homeowner association regulations. It's crucial to check local guidelines before installation, as there might be restrictions on fence heights to maintain visual harmony and prevent obstruction of views. The history of copper craft wire dates back to ancient civilizations where it was used for practical purposes, such as jewelry making and architectural embellishments. Over time, it evolved into a form of artistic expression, reflecting cultural narratives and personal stories. From the elaborate Celtic knotwork to the delicate Native American designs, copper wire has been a universal symbol of creativity and craftsmanship. Another significant advantage of bulk extension springs is their compact design The process of joint reinforcement involves careful planning and execution. Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction

Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction joint reinforcement masonry. These bars, known as masonry ties, are designed to bond with the mortar and the masonry units, creating a cohesive structure. Alternatively, fibers can also be used, particularly in modern, more innovative construction methods, offering similar benefits with a different approach. Step 4 Position the Cage When selecting a global wire supplier, several factors come into play. The supplier's reputation, quality certifications, and compliance with industry regulations are paramount. Additionally, their capacity to deliver large volumes, ability to meet tight deadlines, and customer service are critical considerations. A supplier's sustainability practices and environmental impact also weigh heavily in today's market, as more companies strive for eco-friendly sourcing. 1. In your Spring controller or service class, call the `compressVideo` and `decompressVideo` methods from the `VideoCompressionService` class to handle video compression and decompression respectively. 5. Experiment with Different Techniques Once you're comfortable with the basics, start experimenting with different techniques. Try weaving the wire through stems, twisting it into intricate patterns, or even embedding it into floral foam for a more permanent solution. The possibilities are endless! Factors Affecting Cattle Panel Fence Price 제목 리브 라스티드 스테인レス Steel의 진화와 아름다움 Another advantage of conical coil springs is their ability to store and release energy efficiently. The cone shape of the spring allows for a more compact design that can store a large amount of energy in a smaller space compared to a cylindrical spring of the same size

joint reinforcement masonry. These bars, known as masonry ties, are designed to bond with the mortar and the masonry units, creating a cohesive structure. Alternatively, fibers can also be used, particularly in modern, more innovative construction methods, offering similar benefits with a different approach. Step 4 Position the Cage When selecting a global wire supplier, several factors come into play. The supplier's reputation, quality certifications, and compliance with industry regulations are paramount. Additionally, their capacity to deliver large volumes, ability to meet tight deadlines, and customer service are critical considerations. A supplier's sustainability practices and environmental impact also weigh heavily in today's market, as more companies strive for eco-friendly sourcing. 1. In your Spring controller or service class, call the `compressVideo` and `decompressVideo` methods from the `VideoCompressionService` class to handle video compression and decompression respectively. 5. Experiment with Different Techniques Once you're comfortable with the basics, start experimenting with different techniques. Try weaving the wire through stems, twisting it into intricate patterns, or even embedding it into floral foam for a more permanent solution. The possibilities are endless! Factors Affecting Cattle Panel Fence Price 제목 리브 라스티드 스테인レス Steel의 진화와 아름다움 Another advantage of conical coil springs is their ability to store and release energy efficiently. The cone shape of the spring allows for a more compact design that can store a large amount of energy in a smaller space compared to a cylindrical spring of the same size

conical coil spring. This makes conical coil springs well-suited for applications where space is limited, such as in small engines or machinery. Stainless steel wire cloth, also known as stainless steel mesh or woven wire mesh, is a highly versatile material that has found its way into numerous industrial, commercial, and even domestic applications due to its exceptional properties. This unique fabric is essentially a woven network of fine wires, primarily made from various grades of stainless steel, such as 304, 316, and 317, offering an ideal blend of strength, durability, and corrosion resistance. What are Spring Hooks? Proper installation of cavity wall ties is also essential to ensure their effectiveness. They should be securely fixed into both the inner and outer walls, ensuring that they are not loose or incorrectly positioned. It is recommended to use a professional contractor who is experienced in cavity wall tie installation to ensure the job is done correctly. 3. Customizability Many manufacturers offer custom-made coil springs for sale, allowing you to tailor the specifications to meet your specific requirements. This includes spring rate, diameter, length, and material composition This includes spring rate, diameter, length, and material composition

This includes spring rate, diameter, length, and material composition This includes spring rate, diameter, length, and material composition

This includes spring rate, diameter, length, and material composition This includes spring rate, diameter, length, and material composition coil springs for sale. Our coil springs are available in a variety of sizes and styles to fit a wide range of vehicles

coil springs for sale. Our coil springs are available in a variety of sizes and styles to fit a wide range of vehicles coil over springs for sale. Whether you drive a car, truck, SUV, or van, we have the perfect springs to suit your needs. We also offer custom-made springs for those looking for a more personalized solution. In the domain of home decor, pink craft wire finds its place in wall art, candle holders, and even functional items like coat hangers. Its flexibility allows for innovative designs that can match any interior style, from bohemian to minimalist. The design and placement of brick ties are critical elements in any construction project. They must be corrosion-resistant to withstand the harsh elements over time. The choice of material, size, and spacing of ties depends on factors such as the width of the cavity, the load the wall will bear, and the local building codes The choice of material, size, and spacing of ties depends on factors such as the width of the cavity, the load the wall will bear, and the local building codes

coil over springs for sale. Whether you drive a car, truck, SUV, or van, we have the perfect springs to suit your needs. We also offer custom-made springs for those looking for a more personalized solution. In the domain of home decor, pink craft wire finds its place in wall art, candle holders, and even functional items like coat hangers. Its flexibility allows for innovative designs that can match any interior style, from bohemian to minimalist. The design and placement of brick ties are critical elements in any construction project. They must be corrosion-resistant to withstand the harsh elements over time. The choice of material, size, and spacing of ties depends on factors such as the width of the cavity, the load the wall will bear, and the local building codes The choice of material, size, and spacing of ties depends on factors such as the width of the cavity, the load the wall will bear, and the local building codes The choice of material, size, and spacing of ties depends on factors such as the width of the cavity, the load the wall will bear, and the local building codes The choice of material, size, and spacing of ties depends on factors such as the width of the cavity, the load the wall will bear, and the local building codes

The choice of material, size, and spacing of ties depends on factors such as the width of the cavity, the load the wall will bear, and the local building codes The choice of material, size, and spacing of ties depends on factors such as the width of the cavity, the load the wall will bear, and the local building codes brick tie detail. Throughout its journey, the snake encounters various obstacles and challenges, each one pushing it to its limits and forcing it to grow and evolve

brick tie detail. Throughout its journey, the snake encounters various obstacles and challenges, each one pushing it to its limits and forcing it to grow and evolve The Metal Basket Tree became more than just an art installation; it became a symbol of hope and inspiration. It reminded us that even in our technologically advanced world, there is still room for creativity and wonder. It showed us that we can find beauty in unexpected places and that sometimes, the most extraordinary things are hidden in plain sight. Masonry Joint Reinforcement A Key Factor in Structural Integrity When working with thick metal wire, it's important to remember that it can be difficult to work with due to its stiffness. However, there are several techniques you can use to manipulate the wire and achieve the desired shape. For example, you can use pliers to bend and shape the wire, or you can use a torch to heat the wire and make it more malleable. With a little practice, you'll be able to create beautiful and intricate designs with thick metal wire. In the realm of manufacturing, weldmesh suppliers play a pivotal role. These dedicated providers offer a wide range of steel mesh products that are essential for various industrial applications. From construction sites to automotive factories, weldmesh is used to reinforce concrete, provide stability in soil, and support heavy loads. The term wrought refers to the process of working iron by hammering or forging, giving it its distinct character and strength. Unlike cast iron, which is molten and then poured into molds, wrought iron is shaped while hot, resulting in a product that is more malleable and less brittle. The wire form of wrought iron is created through a series of drawing processes where the heated iron is pulled through successively smaller dies, refining its shape and consistency. Incorporating 10mm angle beads into your next project will not only add a touch of sophistication but also demonstrate your commitment to detail and craftsmanship. As you thread each bead onto your wire or thread, consider how each angle connects, transforming a simple concept into a wearable work of art. One of the key advantages of galvanized mesh fencing is its versatility. It can be used to create a variety of fences, including privacy fences, pool fences, and security fences. The open design of the mesh allows for easy visibility, making it an excellent choice for security purposes. Additionally, the fence can be easily customized to fit your specific needs, whether you need a tall fence for added privacy or a shorter fence for a more open feel. These connections, often referred to as brick ends ties, are an integral part of brickwork. They serve to bind individual bricks together, ensuring that the structure remains stable and secure over time. The process of creating these ties involves carefully cutting and fitting bricks at specific points, allowing them to interlock and support one another. The '47%' in the term refers to the openness or wire spacing of the fence. This percentage indicates how much of the fence is open, allowing for a certain level of transparency. In this case, 47% of the fence is not obstructed by wires, which can be advantageous in several ways. It enables better visibility for both the farmer and the animals, allowing for easier monitoring of the herd. Moreover, this openness also allows for air circulation, which can be beneficial for pasture health. Using the small tomato cage is simple and straightforward. Simply place the cage over your tomato plant when it is young and start training the stems to grow through the openings in the cage. As the plant grows, continue to guide the stems through the cage, providing support and preventing them from bending or breaking. Once the tomato plant reaches the top of the cage, it will begin to produce fruit.

The Metal Basket Tree became more than just an art installation; it became a symbol of hope and inspiration. It reminded us that even in our technologically advanced world, there is still room for creativity and wonder. It showed us that we can find beauty in unexpected places and that sometimes, the most extraordinary things are hidden in plain sight. Masonry Joint Reinforcement A Key Factor in Structural Integrity When working with thick metal wire, it's important to remember that it can be difficult to work with due to its stiffness. However, there are several techniques you can use to manipulate the wire and achieve the desired shape. For example, you can use pliers to bend and shape the wire, or you can use a torch to heat the wire and make it more malleable. With a little practice, you'll be able to create beautiful and intricate designs with thick metal wire. In the realm of manufacturing, weldmesh suppliers play a pivotal role. These dedicated providers offer a wide range of steel mesh products that are essential for various industrial applications. From construction sites to automotive factories, weldmesh is used to reinforce concrete, provide stability in soil, and support heavy loads. The term wrought refers to the process of working iron by hammering or forging, giving it its distinct character and strength. Unlike cast iron, which is molten and then poured into molds, wrought iron is shaped while hot, resulting in a product that is more malleable and less brittle. The wire form of wrought iron is created through a series of drawing processes where the heated iron is pulled through successively smaller dies, refining its shape and consistency. Incorporating 10mm angle beads into your next project will not only add a touch of sophistication but also demonstrate your commitment to detail and craftsmanship. As you thread each bead onto your wire or thread, consider how each angle connects, transforming a simple concept into a wearable work of art. One of the key advantages of galvanized mesh fencing is its versatility. It can be used to create a variety of fences, including privacy fences, pool fences, and security fences. The open design of the mesh allows for easy visibility, making it an excellent choice for security purposes. Additionally, the fence can be easily customized to fit your specific needs, whether you need a tall fence for added privacy or a shorter fence for a more open feel. These connections, often referred to as brick ends ties, are an integral part of brickwork. They serve to bind individual bricks together, ensuring that the structure remains stable and secure over time. The process of creating these ties involves carefully cutting and fitting bricks at specific points, allowing them to interlock and support one another. The '47%' in the term refers to the openness or wire spacing of the fence. This percentage indicates how much of the fence is open, allowing for a certain level of transparency. In this case, 47% of the fence is not obstructed by wires, which can be advantageous in several ways. It enables better visibility for both the farmer and the animals, allowing for easier monitoring of the herd. Moreover, this openness also allows for air circulation, which can be beneficial for pasture health. Using the small tomato cage is simple and straightforward. Simply place the cage over your tomato plant when it is young and start training the stems to grow through the openings in the cage. As the plant grows, continue to guide the stems through the cage, providing support and preventing them from bending or breaking. Once the tomato plant reaches the top of the cage, it will begin to produce fruit. Another advantage of using stainless steel thin coat angle bead is its excellent resistance to rust and corrosion. This makes it an ideal choice for use in areas that are prone to moisture exposure, such as bathrooms, kitchens, and outdoor environments. The stainless steel material is also easy to clean and maintain, ensuring that it will retain its appearance and functionality for years to come

stainless steel thin coat angle bead. Concrete Reinforcing Mesh Suppliers The Backbone of Infrastructure Development Welded mesh sheets also exhibit excellent corrosion resistance when galvanized or coated, extending their lifespan in outdoor or corrosive environments. This adaptability, coupled with their inherent strength, makes them a go-to material in numerous sectors.

Coil Wire Spring are essential components of a variety of mechanical systems, providing elasticity and flexibility for a variety of applications. Among the different types of Coil Wire Springs, utility tension springs, general-purpose Coil Wire Springs, conical Coil Wire Springs, and rigid Coil Wire Springs are widely used for their specific properties and functions.