Links:

-

Reflective blue glass, a material that captivates the imagination with its mesmerizing appearance, offers a unique perspective on the world. This type of glass, often used in architectural designs and automotive applications, reflects light in a way that creates a sense of depth and movement. When sunlight or artificial light hits reflective blue glass, it is scattered in various directions, creating a stunning visual effect. The Affordable Elegance of 8mm Frosted Glass Price Intrigued by the mystery, Isabelle purchased the mirror, despite Mr

- Calculation of bearing capacity In recent years, architects and designers have embraced reflective laminated glass as a tool to create unique, visually striking structures. From towering skyscrapers with shimmering facades to minimalist homes with sleek glass walls, this material has transformed the architectural landscape, pushing the boundaries of design possibilities. In modern architecture, reflective float glass is used to create stunning visual effects and control the amount of natural light that enters a space. Skyscrapers clad in this material shimmer like mirrored pillars, their surfaces reflecting the ever-changing canvas of the sky. By day, they echo the blues and whites of the clouds; by night, they emulate the city’s illuminated grid, a pulsating heart of artificial light. How to Install Low-E Glass If you have a small bathroom with limited wall space, consider adding a decorative shelf or ledge below your window. This can provide additional storage space for toiletries or decorative items, as well as create a focal point for the room

Conclusion

Glass, often seen as fragile, is also incredibly durable. Our tempered glass products, like the sturdy glass coffee mugs and durable glass cookware, showcase this strength. They are built to withstand the rigors of daily use while maintaining their pristine appearance. Tinted glass sheets also find application in the production of electronic displays. Specialized tinted glasses are used to filter out specific wavelengths of light, improving the screen's contrast and visual clarity. In solar panels, tinted glass helps to increase energy absorption and efficiency by filtering out unnecessary light. In conclusion, coated float glass represents a significant advancement in the field of glass technology. Its combination of thermal insulation, safety, and durability make it an ideal choice for a wide range of applications in the construction, automotive, and other industries. As demand for energy-efficient and safe building materials continues to grow, coated float glass is poised to play an increasingly important role in shaping our built environment. Overall, float glass tempered is a superior choice for anyone looking for a durable, versatile, and visually appealing glass option. Its strength and resilience make it a smart investment for any project, whether it's a small home renovation or a large commercial construction project. With its many benefits and aesthetic appeal, float glass tempered is sure to be a popular choice for years to come. Beyond its aesthetic appeal, the Valentia Silver Mirror is a symbol of resilience. The use of high-quality materials ensures its durability, allowing it to withstand the passage of time and maintain its brilliance. It is a testament to the enduring nature of true craftsmanship, a piece that can be passed down through generations, each reflection carrying the memories of those who have gazed into it. For interior designers, frosted glass is a versatile medium that can be wielded to craft partitions, decorative panels, or even artistic installations

buy frosted glass. Its matte finish provides texture and depth, breaking the monotony of plain surfaces. And when it's time for illumination, frosted glass lampshades cast a dance of patterns on walls, bringing static rooms to life with moving shadows and shapes.

buy frosted glass. Its matte finish provides texture and depth, breaking the monotony of plain surfaces. And when it's time for illumination, frosted glass lampshades cast a dance of patterns on walls, bringing static rooms to life with moving shadows and shapes. Caring for Your Glassware

Ultra clear glass, also known as low iron glass, is a type of glass that is highly transparent and has minimal greenish tint compared to regular clear glass. It is made using high quality silica sand with very low iron content, which gives it its exceptional clarity. Ultra clear glass is increasingly becoming popular in the architectural and interior design industries due to its aesthetically pleasing appearance and versatility. One of the key advantages of patterned glass is its ability to transform ordinary windows into works of art. By incorporating intricate designs or bold patterns, this type of glass adds a layer of depth and character to any room. Whether you prefer the subtle elegance of a subtle damask pattern or the bold statement of a geometric design, patterned glass allows you to express your personal style while also providing privacy and light control. In conclusion, thin mirror glass is a truly remarkable material that combines the best of both worlds. Its exceptional thinness and high reflectivity make it an invaluable tool for a wide range of applications, from enhancing the performance of electronic devices to creating stunning works of art. As we continue to push the boundaries of what is possible with this fascinating material, we can look forward to even more exciting developments in the future. Moreover, the versatility of tempered acid etched glass allows for customization

tempered acid etched glass. Designs, patterns, or logos can be etched onto the glass, turning it into a functional piece of art. It can be clear, translucent, or opaque, providing varying levels of transparency according to the design preference.

tempered acid etched glass. Designs, patterns, or logos can be etched onto the glass, turning it into a functional piece of art. It can be clear, translucent, or opaque, providing varying levels of transparency according to the design preference.

Slumping flo>>>at glass represents a remarkable fusion of art and science, allowing for the creation of stunning, functional pieces that enrich our environment. As technology advances and designers continue to push boundaries, the future of slumping float glass will undoubtedly hold even more exciting innovations and applications. Whether it’s enhancing architectural aesthetics or adding artistic flair to everyday objects, slumped glass showcases the limitless potential of creativity and craftsmanship in the contemporary glass industry.

Aside from its visual and practical benefits, tinted black glass also possesses symbolic significance. It represents a barrier—a line between the exterior world and personal space. This characteristic can evoke feelings of mystery and intrigue, encouraging a sense of curiosity from those outside looking in. As a reflective surface, black glass can also create an interplay with light, casting dramatic shadows and reflections that enhance the ambiance of a room.

Apart from privacy, tinted glass also offers several aesthetic benefits

One of the most significant advantages of high reflective glass is its versatility. It can be used in a wide range of applications, from residential buildings to commercial spaces, and from interior walls to large-scale facades. Its ability to seamlessly integrate into various design schemes makes it an ideal choice for architects and designers seeking to create modern, sustainable, and aesthetically pleasing environments Its ability to seamlessly integrate into various design schemes makes it an ideal choice for architects and designers seeking to create modern, sustainable, and aesthetically pleasing environments

One of the most significant advantages of high reflective glass is its versatility. It can be used in a wide range of applications, from residential buildings to commercial spaces, and from interior walls to large-scale facades. Its ability to seamlessly integrate into various design schemes makes it an ideal choice for architects and designers seeking to create modern, sustainable, and aesthetically pleasing environments Its ability to seamlessly integrate into various design schemes makes it an ideal choice for architects and designers seeking to create modern, sustainable, and aesthetically pleasing environments Its ability to seamlessly integrate into various design schemes makes it an ideal choice for architects and designers seeking to create modern, sustainable, and aesthetically pleasing environments Its ability to seamlessly integrate into various design schemes makes it an ideal choice for architects and designers seeking to create modern, sustainable, and aesthetically pleasing environments

Its ability to seamlessly integrate into various design schemes makes it an ideal choice for architects and designers seeking to create modern, sustainable, and aesthetically pleasing environments Its ability to seamlessly integrate into various design schemes makes it an ideal choice for architects and designers seeking to create modern, sustainable, and aesthetically pleasing environments high reflective glass. Another benefit of rain pattern glass is its practicality

high reflective glass. Another benefit of rain pattern glass is its practicality

rain pattern glass. The textured surface of the glass is easy to clean and maintain, making it a low-maintenance option for busy households and commercial spaces. Additionally, the added privacy provided by the glass can help to reduce glare and protect furnishings from fading due to UV exposure.

02

Furthermore, white reflective glass can be used to create dynamic and visually striking facades

white reflective glass. The reflective surface can change appearance depending on the angle of view and the lighting conditions, creating a constantly changing and dynamic effect that adds interest and intrigue to a building's exterior.

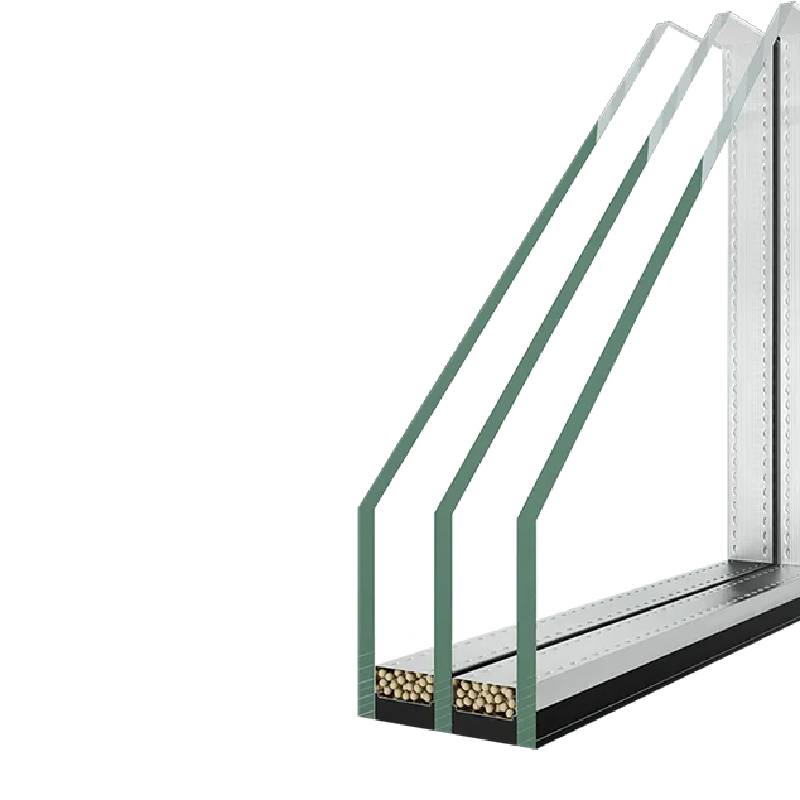

Moreover, tempered insulated glass units are increasingly popular in specialized environments such as laboratories and clean rooms, where durability and cleanliness are crucial. Their ability to withstand temperature fluctuations without breaking makes them ideal for various industrial applications as well.

The Cost of Tempered Glass per Square Foot An In-Depth Analysis I felt a connection to this mirror, a sense of kinship with its silent beauty and timeless elegance

burnished silver mirror. In a world that was constantly changing and evolving, the burnished silver mirror seemed like a beacon of stability and grace, a reminder of the enduring power of art and craftsmanship. Grey low E glass is a versatile and energy-efficient solution for various applications in the construction industry. Its ability to reduce heat loss and gain, improve comfort, and enhance aesthetics makes it a popular choice among homeowners, architects, and builders. As awareness of the importance of energy efficiency and sustainability continues to grow, grey low E glass is expected to play an increasingly important role in shaping the future of building design and construction. The key to Low-E glass's energy-saving properties lies in its ability to limit the transfer of heat through the glass. In the winter, the reflective layer helps retain the warmth inside the building by reflecting infrared radiation back into the room. Conversely, in the summer, the same layer prevents heat from entering the building by reflecting it away from the glass. In conclusion, patterned glass sheets are far more than mere decorations; they are architectural elements that breathe life into space. They manipulate light and vision, providing privacy and beauty, all while enduring the test of time. These exquisite glasses stand as a reminder of how functionality and art can coalesce to elevate our built environments.

burnished silver mirror. In a world that was constantly changing and evolving, the burnished silver mirror seemed like a beacon of stability and grace, a reminder of the enduring power of art and craftsmanship. Grey low E glass is a versatile and energy-efficient solution for various applications in the construction industry. Its ability to reduce heat loss and gain, improve comfort, and enhance aesthetics makes it a popular choice among homeowners, architects, and builders. As awareness of the importance of energy efficiency and sustainability continues to grow, grey low E glass is expected to play an increasingly important role in shaping the future of building design and construction. The key to Low-E glass's energy-saving properties lies in its ability to limit the transfer of heat through the glass. In the winter, the reflective layer helps retain the warmth inside the building by reflecting infrared radiation back into the room. Conversely, in the summer, the same layer prevents heat from entering the building by reflecting it away from the glass. In conclusion, patterned glass sheets are far more than mere decorations; they are architectural elements that breathe life into space. They manipulate light and vision, providing privacy and beauty, all while enduring the test of time. These exquisite glasses stand as a reminder of how functionality and art can coalesce to elevate our built environments.

decorative bathroom window. Adding a potted plant or some decorative accents on the shelf can also help tie the look of the window into the rest of the bathroom decor. One of the key advantages of patterned perspex panels is their ability to diffuse light. When placed in large windows or skylights, they soften natural light, creating a warm and inviting atmosphere. This makes them particularly well-suited for living rooms, bedrooms, and offices where a comfortable and relaxing ambiance is desired. 1. Education Float glass video can transform the way students learn, providing immersive and interactive educational experiences that are engaging and effective.

Maintenance and Care

Sun ban reflective glass is a type of glass that is specifically designed to reduce the amount of heat and glare that enters a building from the sun. This type of glass has a special coating that reflects the sun's rays, keeping the interior of a building cooler and more comfortable. Low-E glass is a type of coated glass that is designed to reduce the transfer of heat through the window. It works by reflecting infrared radiation, which is the type of heat that causes our homes and offices to feel warm in the winter and cool in the summer. By reducing the amount of heat that escapes or enters a building, Low-E glass helps to maintain a comfortable indoor temperature, resulting in significant energy savings.

Beyond aesthetics, aluminum standing mirrors are functional assets to any home. The reflective surface allows individuals to check their appearance from head to toe, ensuring they feel confident before stepping out. Many modern designs also incorporate additional features, such as adjustable stands or the ability to tilt, providing users with the flexibility to position the mirror at the perfect angle. Some mirrors even come with built-in LED lighting, allowing for better visibility during dressing or grooming.

Float glass itself, invented in the mid-20th century, involves a process where molten glass is floated on molten tin to create a smooth, uniform sheet. The addition of colorants to this process transforms the ordinary into the extraordinary. Colorants, derived from metal oxides, are infused into the molten glass, producing a multitude of hues. Common colorants include cobalt for blue, chromium for green, and manganese for violet. The beauty of coloured float glass lies not only in its vivid colors but also in its ability to interact with light, creating dynamic visual effects that vary throughout the day.

One of the standout features of the silver slim mirror is its versatility. It can be used in a variety of settings, from the bedroom to the bathroom, and from the living room to the entryway. Its compact size makes it perfect for small spaces, while its timeless design ensures that it will never go out of style. Whether you're getting ready for a night out or simply want to check your appearance before heading out the door, the silver slim mirror is always at hand to help you look your best Whether you're getting ready for a night out or simply want to check your appearance before heading out the door, the silver slim mirror is always at hand to help you look your best

Whether you're getting ready for a night out or simply want to check your appearance before heading out the door, the silver slim mirror is always at hand to help you look your best Whether you're getting ready for a night out or simply want to check your appearance before heading out the door, the silver slim mirror is always at hand to help you look your best

Whether you're getting ready for a night out or simply want to check your appearance before heading out the door, the silver slim mirror is always at hand to help you look your best Whether you're getting ready for a night out or simply want to check your appearance before heading out the door, the silver slim mirror is always at hand to help you look your best silver slim mirror. Another advantage of grey float glass is its transparency. Unlike opaque glass, which can block out light and, grey float glass allows natural light to filter through, creating a bright and airy space. This makes it an ideal choice for large windows and doors, as well as for partitions and room dividers. In the automotive industry, anti-glare glass sheet has become a popular choice for car windshields and displays. The anti-glare properties of the glass help to reduce distractions for drivers, enabling them to focus on the road ahead. This not only improves safety but also enhances the overall driving experience. In addition, the technology also helps to reduce eye strain for passengers, making long journeys more comfortable. In addition to its practical benefits, frosted brown glass also adds a touch of luxury to any space. The brown hue adds richness and depth to the glass, making it a perfect choice for those looking to create a cozy and sophisticated atmosphere. Whether used in windows, doors, or as a decorative accent, frosted brown glass instantly elevates the look and feel of a room.

silver slim mirror. Another advantage of grey float glass is its transparency. Unlike opaque glass, which can block out light and, grey float glass allows natural light to filter through, creating a bright and airy space. This makes it an ideal choice for large windows and doors, as well as for partitions and room dividers. In the automotive industry, anti-glare glass sheet has become a popular choice for car windshields and displays. The anti-glare properties of the glass help to reduce distractions for drivers, enabling them to focus on the road ahead. This not only improves safety but also enhances the overall driving experience. In addition, the technology also helps to reduce eye strain for passengers, making long journeys more comfortable. In addition to its practical benefits, frosted brown glass also adds a touch of luxury to any space. The brown hue adds richness and depth to the glass, making it a perfect choice for those looking to create a cozy and sophisticated atmosphere. Whether used in windows, doors, or as a decorative accent, frosted brown glass instantly elevates the look and feel of a room. 3. Annealing After floating, the glass is gradually cooled in an annealing lehr to relieve internal stresses, ensuring durability and preventing breakage.

In conclusion, low e soft coat glass stands out as a testament to how technological advancements can harmoniously blend with design aesthetics to create materials that are not only practical but also beautiful. Its ability to provide thermal efficiency, reduce glare, offer customization options, and ensure longevity makes it a valuable asset in the world of construction and design. As we move towards more sustainable living and working spaces, the allure of low e soft coat glass is poised to shine even brighter. The Art and Function of Patterned Perspex Panels It is also important to consider the energy efficiency benefits of replacing an inefficient IGU. Newer IGUs with low-emissivity coatings and argon gas fillings can significantly reduce heat loss and improve the overall comfort of your home. Additionally, upgrading to energy-efficient IGUs can result in lower energy bills and increased resale value.

The Role of Sustainability

tempered glass manufacturers