-

Add: HeBei ShengShi HongBang Cellulose Technology CO.,LTD.

-

Email

13180486930@163.com -

CONTACT US

+86 13180486930

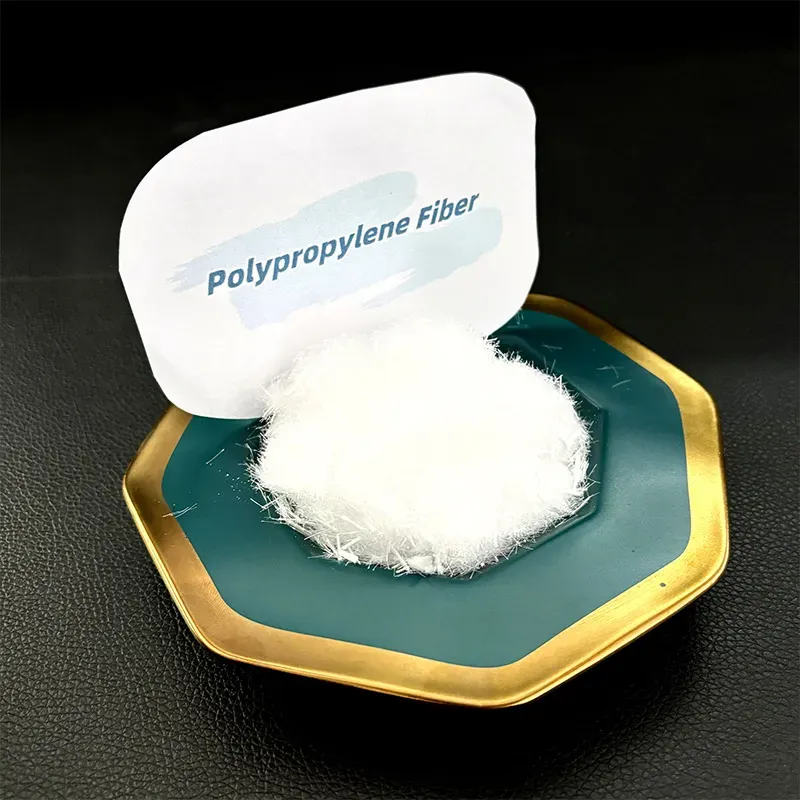

Polypropylene Fiber in Construction Enhancing Durability

The construction industry is increasingly embracing advanced materials to meet the demands for stronger, more durable, and sustainable structures. Polypropylene fiber has emerged as a transformative component in this evolution, particularly in concrete applications where its unique properties address critical challenges like cracking, shrinkage, and impact resistance. Alongside specialized variants such as polypropylene fibres for concrete, these solutions are reshaping modern construction practices. This article explores their technical advantages, practical uses, and contributions to resilient infrastructure.

Properties and Applications of Polypropylene Fibres for Concrete

Polypropylene fibres for concrete are engineered to improve the mechanical and physical properties of cementitious matrices. Manufactured from high-quality polypropylene polymers, these fibres are inert, corrosion-resistant, and compatible with concrete mixes, making them ideal for enhancing durability without compromising structural integrity.

In concrete, these fibres act as micro-reinforcements, bridging cracks and limiting their propagation during early-age shrinkage or mechanical loading. They reduce the formation of plastic shrinkage cracks by stabilizing the moisture distribution in the fresh mix, a common issue that weakens concrete over time. Additionally, polypropylene fibres for concrete improve impact resistance and ductility, making them suitable for applications subjected to dynamic loads, such as industrial floors, bridge decks, and precast elements. Their lightweight nature also minimizes the risk of segregation during mixing, ensuring uniform distribution and consistent performance.

Advantages of Microfiber Synthetic in High-Performance Composites

Microfiber synthetic refers to ultra-fine polypropylene fibres designed to address the micro-cracking challenges in high-strength concrete and composite materials. With diameters in the micron range, these fibres provide enhanced surface area for bonding with the cement paste, creating a dense network that resists the initiation of cracks at the microscale.

In high performance concrete used in skyscrapers, tunnels, and marine structures, microfiber synthetic improves tensile strength and fatigue resistance, extending the service life of structures exposed to harsh environments. They also enhance the fire resistance of concrete by reducing explosive spalling during elevated temperatures, a critical safety feature in commercial and residential buildings. Furthermore, these fibres can be combined with other reinforcement materials like steel or fiberglass to create hybrid systems that balance strength, ductility, and cost-effectiveness.

Role of Fiberglass Mesh for Concrete in Structural Reinforcement

Fiberglass mesh for concrete serves as a versatile reinforcement solution, particularly in applications requiring non-corrosive and dimensionally stable materials. Made from alkali-resistant glass fibres embedded in a polymer matrix, this mesh provides tensile strength to plaster, render, and concrete overlays, preventing cracking and improving load distribution.

In masonry structures, fiberglass mesh for concrete is used to reinforce exterior insulation and finish systems, ensuring long-term durability of facades exposed to weathering and thermal cycling. It is also critical in concrete repair and rehabilitation, where it stabilizes damaged surfaces and enhances the bond between new and existing materials. Unlike traditional steel mesh, fiberglass mesh does not rust, making it ideal for coastal constructions or environments with high moisture content, where corrosion would compromise steel reinforcement.

Technical Considerations for Polypropylene Fiber Reinforcement

Effective use of polypropylene fiber and fiberglass mesh for concrete requires careful consideration of material selection, mix design, and installation practices. For polypropylene fibres for concrete, the dosage rate is determined based on specific applications and desired performance criteria, with proper adjustments to maintain workability and structural balance.

For fiberglass mesh for concrete, the mesh specifications must align with structural requirements to ensure adequate coverage and load transfer without compromising surface finishes. Proper installation, including correct placement within the concrete matrix or overlay, is essential to maximize reinforcement efficiency and avoid premature failure.

Polypropylene Fibres for Concrete FAQs

How Do Polypropylene Fibres for Concrete Reduce Crack Formation?

Polypropylene fibres for concrete act as crack arrestors by bridging developing cracks, limiting their growth and reducing the overall crack width. They also improve the plastic shrinkage resistance of fresh concrete by stabilizing moisture evaporation, a primary cause of early-age cracking.

What Makes Microfiber Synthetic Suitable for High-Temperature Environments?

Microfiber synthetic exhibits excellent thermal stability and reduces explosive spalling in concrete exposed to fire. Their low melting point allows them to create pathways for steam escape, preventing internal pressure buildup and maintaining structural integrity during fires.

Can Fiberglass Mesh for Concrete Replace Steel Reinforcement?

Fiberglass mesh for concrete is not a direct replacement for steel in load-bearing structures but is ideal for non-structural reinforcement, such as crack control in renders, plasters, and thin concrete overlays. It offers superior corrosion resistance in environments where steel would degrade.

How Does Aspect Ratio Affect Microfiber Synthetic Performance?

A higher aspect ratio of microfiber synthetic enhances their ability to bridge cracks and improve tensile strength, as longer fibres create a more interconnected network within the concrete matrix.

What Maintenance Benefits Do Fiberglass Mesh for Concrete Offer?

Using fiberglass mesh for concrete reduces long-term maintenance costs by minimizing crack-related damage, particularly in exposed surfaces. Its non-corrosive nature eliminates the need for anti-rust treatments, making it a cost-effective solution for durable infrastructure.

In conclusion, polypropylene fiber and fiberglass mesh for concrete represent a paradigm shift in construction materials, offering innovative solutions to enhance durability, sustainability, and performance. These materials address critical challenges across various applications, from preventing early-age cracks in concrete to reinforcing structural overlays in harsh environments. As the industry continues to prioritize resilience and eco-friendliness, their roles in creating long-lasting, low-maintenance structures will only grow, solidifying their position as essential components of modern construction.

-

The Function of Polymer Powder in Thin-Bed MortarsNewsAug.25,2025

-

Polypropylene Fiber for Waterproofing MembranesNewsAug.25,2025

-

Starch Ether as a Thickener in Construction GroutsNewsAug.25,2025

-

Rubber Powder as a Sustainable Additive in GroutsNewsAug.25,2025

-

Gypsum Retarder Chemical Dosage and Its Precise EffectsNewsAug.25,2025

-

Using HPMC to Reduce Cracking in Cementitious ProductsNewsAug.25,2025

-

Wood-Based FibresNewsAug.20,2025